Gypsum is the material that is widely used for industrial material and building material. Gypsum jaw crusher is used to crush gypsum, which has pertinence, strong applicability, and high feasibility. Therefore, the stone crusher machine is different from other stone crushers like concrete crushers, impact rock crushers, cone crusher machine, hammer crushers, sand making crushers, portable rock crushers, rock crushing machine.

Gypsum Jaw crusher is economical, which has the advantages of environmental protection, convenient operation and maintenance, high production efficiency.

Gypsum jaw crusher is applied in mines, building materials, infrastructure, and other departments as the primary crusher. According to the width of the feed port, it can be divided into three kinds: large, medium and small. The width of the feeding port of gypsum jaw crusher is larger than 600mm, the width of the feed port is the medium machine, and the width of the feed port is smaller than the 300mm is a minicomputer. The utility model has the characteristics of simple structure, easy manufacture, reliable operation and so on.

Because of the advantages of gypsum jaw crusher with simple structure, reliable work, being capable of crushing hard materials and so on. This kind of stone jaw crusher is also widely used in the fields of ore dressing, building materials, silicate, ceramics, smelting, highway, railway, water conservancy, and chemical industry.

Gypsum is a monoclinic mineral and hydrate with the main chemical composition of calcium sulfate. Usually, the gypsum appears white, colorless, transparent crystal, sometimes due to impurities and gray, light yellow, light brown and other colors.

What is gypsum? Does it have any connection with the jaw crusher?

Gypsum is a monoclinic mineral and hydrate with the main chemical composition of calcium sulfate. Usually, the gypsum appears white, colorless, transparent crystal, sometimes due to impurities and gray, light yellow, light brown and other colors.

Gypsum is a monoclinic mineral and hydrate with the main chemical composition of calcium sulfate. Usually, the gypsum appears white, colorless, transparent crystal, sometimes due to impurities and gray, light yellow, light brown and other colors.

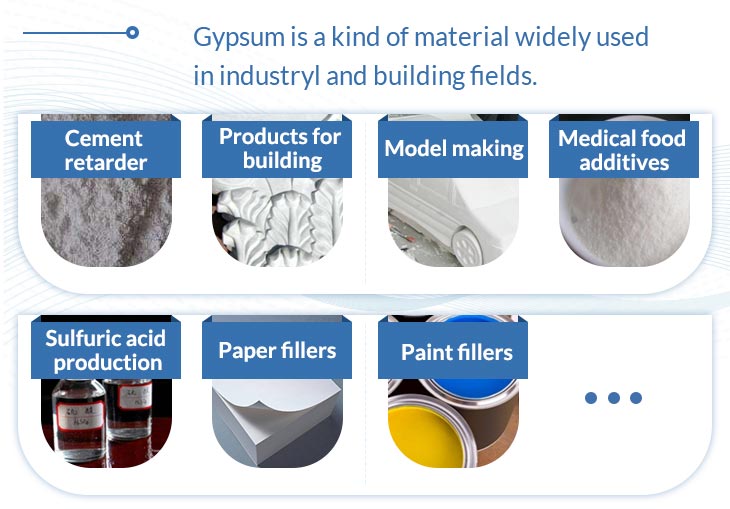

Gypsum is a widely used industrial material and building material. It can be used in cement retarder, gypsum building products, model production, medical food additives, sulfuric acid production, paper filler, paint filler, etc. In addition, owing to the microporous structure of gypsum, whose heating and dehydration properties provide excellent sound insulation, thermal insulation and fire resistance.

Performance Advantage of Gypsum Jaw Crusher Equipment

This stone machine has the advantages of excellent quality and covers a small area: The gypsum jaw crusher is manufactured by absorbing the experience and the technology at home and abroad, the floor area of the crushing machine body is small, the whole machine can be split and installed, the quality of gypsum jaw crusher is light, so the transportation is enough convenient. Simple structure and convenient operation: The gypsum jaw crusher plant is mainly composed of a mobile jaw plate, frame, upper and lower fender, adjustable seat, movable rod, etc. Being of high efficiency, energy conservation, and economic durability: The gypsum jaw crusher has the advantages of high processing capacity, low abrasion and low energy consumption, the energy-saving rate of gypsum jaw crusher equipment can reach 15-30%, the energy-saving of the system is more than double, and the consumption of electric power is relatively low. Gypsum jaw crusher manufactured by China Hongxing is safe and reliable, easy to maintain: The lubricating system of the gypsum jaw crusher is gradually perfect, the transmission parts of the crusher machine are made of high-carbon steel, durable to use, each component is convenient to check and replace, and the maintenance of the crusher equipment is simple.

Recommended Jaw Crusher Machine for Customer Jim Who is From South Africa

Hongxing jaw crusher machine production line / PE-400*600 gypsum jaw crusher, in another word, the one that commonly used as the crusher mode of gypsum jaw crusher production line, 400*600 as material feeding port size, the maximum feeding particle size is 340 mm, the processing capacity of Hongxing Machinery crusher production line varies from 30000MT per year, which belongs to medium and large gypsum jaw crusher equipment.

What is the Price of the Gypsum Jaw Crusher Machine for sale?

Many customers often ask questions like the following. The gypsum jaw crusher produced by Hongxing Mine Heavy Industry Co., Ltd. is often used in the coarse crushing stage. The large block of gypsum is crushed into about 10 centimeters of a small stone in order to carry out the second stage, the third stage fine crushing, and the stone shaping stage. Therefore, the frequency of a single configuration is also relatively small, plus the requirement to configure silo, feeder, conveyor, vibrating screen and other crusher accessories.

our professional technical engineers will design a reasonable jaw crusher machine production line plan according to the customer’s on-site production situation, including equipment selection, scheme configuration and so on. Of course, the gypsum jaw crusher price will be different according to the types.

How much is the gypsum Jaw Crusher Cost with the production of 30000MT per year?

As we all know, gypsum jaw crusher is generally used as a head break in the production line, and its output will directly affect the output of the whole production line. How to improve the production capacity of stone jaw crusher to the maximum extent is a problem that many jaw crushers manufacturers are most concerned about.

As we all know, Hongxing Machinery jaw crushers enjoy the feature with strong compressive wear resistance.

- Ensure an adequate volume of mineral

During the normal operation of feeder, the feeder device can adjust the knob of the control box within the range of rated amplitude according to the needs of productivity, so as to realize stepless adjustment of feeder productivity.

- Matters of feeding machine of gypsum jaw crusher equipment

Prevent iron from entering the broken cavity. Gypsum blocks may damage jaw plates and other jaw crusher parts.

- The maximum size of gypsum should be smaller than that of the jaw crusher

Large gypsum stones are easy to clog the crushing cavity and affect crushing efficiency.

- Set a reasonable discharging port size

The setting of the discharge port of the jaw crusher machine is to adjust the distance between the two jaw plates at the lower end of the crushing chamber, and the adjustable range of the discharge port of different types of equipment is different.

Too small discharge ports of jaw rock crusher can cause blockage and excessive energy consumption, resulting in severe damage to the gypsum jaw crusher. Excessive discharge ports can increase the second crushing load.

Wide range of cheap gypsum jaw crushers are waiting for you

Do you want to know the latest quote of jaw rock crushers price? Hongxing Machinery provides you with the best service, ensure the long life of stone crushers with multiple types, and fast delivery. Why not come to our factory for a visit?