Do you know what is roll crusher machine?

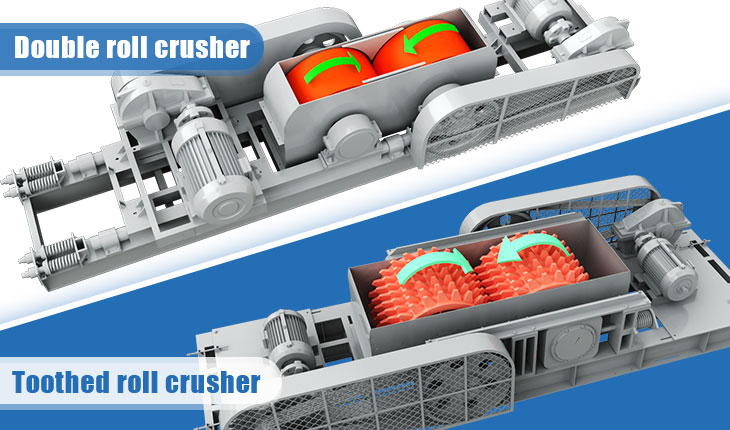

Double roll crusher machine

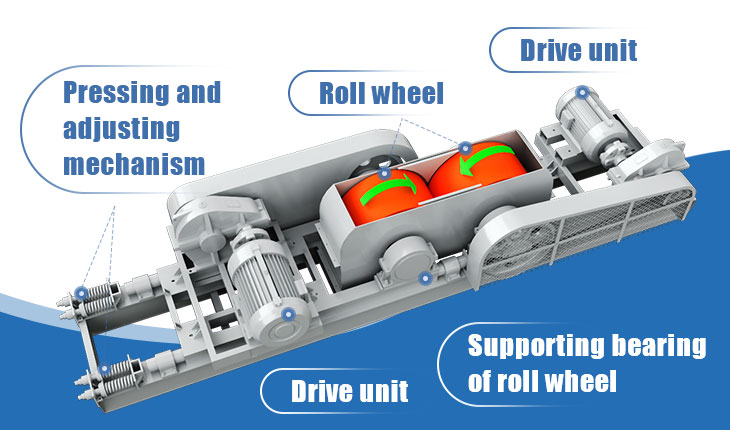

Roll crusher has a simple structure with a less excessive crushing phenomenon. The tooth shape, size, and arrangement of roll surface can be changed with the properties of the material, and the medium-hard and soft ore can be crushed in medium and fine. And, what’s more, the roll crusher equipment is mainly composed of a roller wheel, roller bearing, pressing and regulating device and driving device.

Generally, a double roll crusher often crushes aggregate materials by two rolls, it is suitable for medium and soft stone materials, especially for coal materials.

How does the coal double roll crusher operate?

The driving mechanism is driven mainly by two motors, which is dragged to the slot wheel through a triangular belt and rotates according to the relative direction. When the material is broken, the material passes through the roller through the feeding port, which is crushed and broken, and the finished product is discharged under the chassis. In order to be safe, the transmission part should install the safety cover according to the actual situation. Outstanding advantages of coal double roller crushers: Excellent and efficient crushing TEMP effect: The output of Hongxing double roll crusher is 1.5 times of that of conventional crushers, and the particle size of the finished stone is uniform, the size is reasonable, and the dust content is low. Production cost: There is a broken tooth ring on the double roll crusher, and the wear of the double roll crusher sleeve can be replaced to a certain extent, so as to reduce the downtime and the production cost. Safe and stable operation: The limit rectangular hydraulic coupler not only absorbs the impact force at the time of crushing, but also ensures the smooth operation of the machine, and also has the function of safety protection for the machine. Reduce over crushing and wear parts: The dual function of crushing and screening reduces the over-crushing and energy consumption of the material, prolongs the service life, and has the TEMP effect of shearing and stretching crushing. The material is not easy to be blocked : non-equal round, non-meshing, and non-constant speed operation of two rollers and the phenomenon of material blockage of the roller crusher will be reduced.

The difference between toothed roll crusher and roll crusher machine

Introduction of coal double roller crusher machine

Roll crusher is also called double roll crusher, which is mainly used for fine crushing operation with ore particle size less than 80mm. The utility model has the advantages of small volume, large crushing ratio, low noise, simple structure, and convenient maintenance. The particle size of the broken material is uniform, the over-crushing rate is low, and the particle size of the finished product is 0.5 × 40 mm.

Background of coal toothed roll crushers for sale

The tooth roll crusher is mainly made up of transmission device, frame part, crushing roller, mechanical spring device, linkage mechanism and so on. It is suitable for coal, metallurgy, mining, chemical industry, building materials, and other industries, and toothed roll crusher is more suitable for the crushing of raw coal (including gangue) in large coal mines or coal preparation plants.

The crushing capacity of a toothed roll crusher is large, and the limited distance between motor and reducer to prevent power overload and sensor overload protection, which is safe and reliable.

Distinguish between double roll crusher equipment and toothed roll crusher machine

One of the most simple and intuitive differences between the double roll crusher and the toothed roll crusher is the tooth, in other words, the toothed roll crusher has the tooth, double roll crusher doesn’t have the tooth.

On the other hand, it is possible to distinguish from the mode operation of the apparatus, the drive mechanism of the roller crusher is driven by two motors, by means of a triangular belt drive to the sheave, and rotating in a relative direction. When the material is crushed, the material passes through the roller wheel from the feeding port, is crushed by the rolling, and the broken finished product is discharged from the bottom of the bottom frame.

Hongxing tooth roller crusher adopts special wear-resistant tooth roller to rotate at high speed, and the material is split and broken (the traditional tooth-roller crusher is crushed by low-speed extrusion), and the mechanism of high productivity is formed. The pitch of the toothed roller machine is adjusted hydraulically, and the bearing of the HXJQ toothed roller shaft is lubricated. Generally, the toothed roll crusher has the design of optimization, the tensile shear selection, high-efficiency, low-consumption and uniform discharging granularity.

Roll crusher ( HXJQ manufacturer)are on sale in India

Recently, an Indian customer named Jim has come to HXJQ corporation for purchasing double roll crushers, at first, HXJQ coal roll crusher price has surprised him a lot, cause the roll crushers not only has excellent quality but also great advantages (comparing to other roll crushers). After a conversation with our salesman, Jim has adopted the advice raised by the salesman. Additionally, Jim has also seen the worksite of our crushers on HXJQ website.

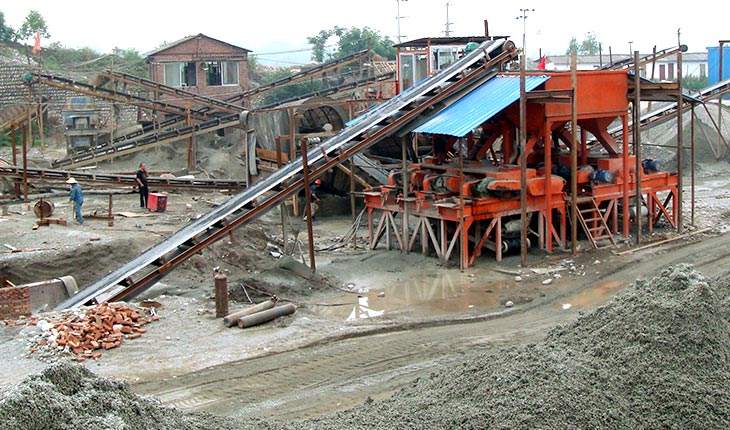

The worksite of HXJQ double roll crusher

Hongxing roll crushers for sale

There are many double roll crusher manufacturers producing this kind of crusher machine, one of the most popular mining crushers manufactures is China HXJQ. As we all know, Hongxing Machinery offers multiple types of double roll crushers, you can choose your ideal crushers according to double roll crushers catalog. There are many double roll crushers for sale.