Do you know what the copper concentrate is?

Copper concentrate is a concentrate of low-grade copper-bearing ore that has been treated by a beneficiation process to achieve a certain quality index, and can be directly supplied to the smelting plant for copper smelting.

There are more than 200 kinds of copper minerals in nature, of which only a dozen copper ores have economic value. The most common copper ores are sulfide copper deposits, such as chalcopyrite (cufes2), chalcopyrite (cu2s), copper orchid (cus) and so on. At present, 80% of the copper ore in the world comes from this kind of ore. When the copper concentrates crushed by Hongxing Machinery crusher machine and ball mill, the copper concentrate is separated and captured by reagent floatation, which greatly improves the grade. In a few copper mines, which are often mixed with malachite, and it is a copper-containing carbonate mineral, the carbonate has beautiful color, and can be made into an ornament such as an ornament or a necklace, and it is a rare gem loved by people.

Imported sulfide copper concentrate is generally becoming from dark green to yellow-green, some copper concentrates are grayish-black, which is mixed with a little blue powder. Copper concentrate is a flotation product with fine particle size. The copper concentrate, which is close to dry, and it is easy to be lost in the process of storage and transportation, however, it is not suitable for ocean transportation, so the copper concentrate is often kept about 10% moisture in the production process. When the temperature is high, the copper sulfide concentrate is easy to oxidize, especially when the ocean transportation time is long, or when the goods are handed over in summer, the oxidation phenomenon is more serious.

When accepting this kind of copper concentrate, the copper grade is often reduced and the receiving weight is increased. It is for this reason that copper concentrate is measured by a total metal content in the process of trade handover. Samples for quality analysis should be sealed in aluminum foil bags. The experimental results show that the copper content of the samples stored in the paper bag or polyethylene bag for one month decreases obviously with the prolongation of the preservation time, while the copper content of the samples stored in the aluminum foil bag does not change obviously even if the samples are stored in the aluminum foil bag for half a year.

To be exactly, copper ore refers to ore mined from ore. While copper concentrate means concentrates from low-grade copper-bearing ore that has been treated to a certain quality by ore beneficiation. Copper concentrates can be directly smelting for smelters.

As we all know, copper concentrate is widely used in the electrical industry, mechanical industry, chemical industry and national defense industry. Copper concentrate is the concentrate with low grade copper-bearing raw ore which has reached a certain quality index through the beneficiation process, which can be directly supplied to the smelter for copper.

The application of copper concentrate

Copper concentrate is also widely applied in crushers, especially for fixed jaw crusher machine, cone crushers, hammer crushers, etc. The “sheep horn copper” obtained from ore smelting is crude copper, and the electrolytic copper with high purity can be obtained by electrolysis. In the process of smelting and electrolysis, gold, silver, palladium, platinum, cadmium, lead, zinc, bismuth, selenium, tellurium, sulfur and other elements or compounds can also be recovered from anode mud, electrolyte, flue ash, and tail gas, respectively. Comprehensive utilization can not only reduce the pollution of waste liquid, waste residue, and waste gas to the environment and air, but also turn waste into treasure, and improve the utilization value of copper concentrate.

With the development of industry around the world, the domestic copper resources can not meet the needs of copper smelters. Many copper smelting enterprises go abroad to purchase copper concentrate raw materials for production.

Hongxing Mining Machinery is no exception. But when northern companies bring goods in winter, the copper concentrate can freeze into pieces and needs to be broken before it can be used, so it needs a crusher to help.

The company’s copper concentrate raw materials mainly come from Russia, Kazakhstan, Mongolia and domestic Xinjiang, Qinghai and other places. Every winter, almost all the copper concentrate raw materials shipped to China are frozen into pieces.

Frozen block crushing process of copper concentrate crushers for sale

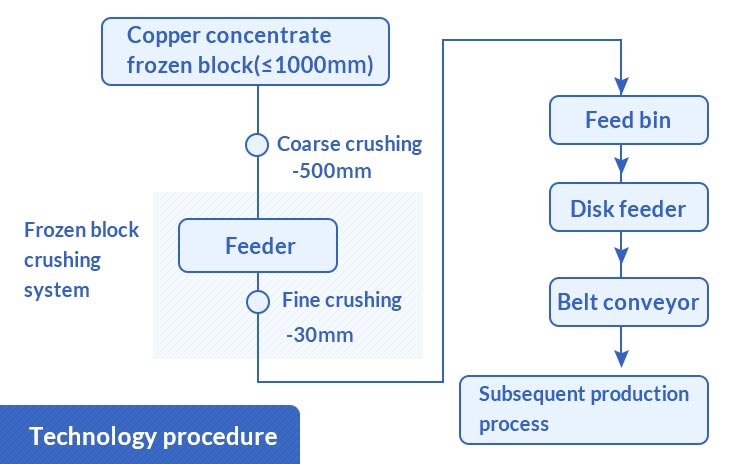

Firstly, the copper concentrate frozen block (≤ 1000mm) is crushed and roughly broken by the scraper. Then, the coarse frozen block (500mm) is fed into the upper hopper of the feeder by grab crane, and the frozen block is crushed into the Hongxing Machinery crushers through the feeder. China Hongxing crushers can process the copper concentrate with 225mm output size, and if the crushed product (30mm) which meets the grain size requirement will be sent into the silo from the lower discharge chute of the body, and then the broken copper concentrate is fed into 2 by the grab crane.

Main crushing equipment cost of copper concentrate of the frozen block

The freezing block crushing system mainly includes feeding equipment and crusher crushing equipment.

Feeding equipment. The main results are as follows: The grain size of copper concentrate frozen block after the coarse crushing of scraper is 500mm. The feeding equipment satisfying the grain size is belt conveyor and vibrating feeder. The belt conveyor has a large feeding particle size of more than 1000 mm, which is suitable for bulk materials with high moisture and mud content.

Hongxing vibrating feeder is of high quality, excellent performance, reasonable low price.

Compared with other feeding and discharging equipment, the belt conveyor has a more complex structure, larger equipment weight, and higher price. The vibrating feeder has the advantages of simple structure, convenient operation, no lubrication, low power consumption, and uniform feeding, but it is not suitable for powder materials with high viscosity and high moisture content and is generally used for feeding and discharging bulk materials below particle size 500mm.

The frozen block of copper concentrate has only occurred simple physical breakage under the action of scraper, and its shape is still frozen bulk material, and there is no problem of high viscosity. According to the performance characteristics of the above two kinds of feeding equipment, the vibrating feeder should be selected for the feeding equipment of the frozen block crushing system.

HXJQ Machinery Crushing Equipment: The frozen block of copper concentrate is a fragile mineral. It is still used to treat the frozen block of copper concentrate by crushers equipment. It is necessary to compare and then select some crushers. The technical performance and characteristic of all kinds of crushers are different. The particle size of the frozen block of the copper concentrate ready to be crushed is 500mm, and the breakability is good.

The particle size of the broken product is required to be 30mm in the following process. Therefore, the crusher of the frozen block crushing system should choose the equipment with high crushing ratio. The crushing of counterattack crusher and hammer crusher is relatively large, which is suitable for the crushing of frozen block of copper concentrate. However, the overall performance of the counterattack crusher is superior to that of the hammer crusher. It can complete the task of two stages of fine crushing at one time has been widely used in the crushing operation of coal and non-metallic mines.

Hongxing Mining Machinery is specialized in offering crushing equipment like fixed jaw crushers, impact rock crushers, portable rock crushers, hydraulic cone crushers, hammer crushers, vibrating feeders, vibrating screens, semi-portable crushers, rock crushers, tracked crushers, etc. Then you can pay a visit to Hongxing factory and purchase multiple types of rock crushers for sale you need.

Impact rock crusher is mainly used in metallurgy, chemical, building materials, hydropower and other materials processing that often requires relocation operations.

As one of the most popular shareholdings large-scale crushing manufacturers, Henan Hongxing Machinery Factory integrates the work of researching, manufacturing and selling together. With more than 40 years of development, so we promise that the crushers you have bought must be of high quality. Want to know Latest Price Quote of crushers? Come on and leave your message!