Why is the small jaw rock crusher so hot at the market and its sales much better than that of the large crusher equipment. It is not only because of the small size, low price and high performance of the small jaw crushers, but it also has so many other advantages that you maybe don’t know. What are the specific advantages of the small jaw rock crushers?

small jaw rock crushers are less space occupied

Wide range of materials can be crushed by the small concrete jaw crusher

Because of the different properties of materials, we need to use different crusher machine to process them. Although It may not be that all materials are suitable for one crusher, the small jaw rocks crusher better than other crushers. In the past, the way we handle garbage is mainly to bury, burn and pour them into the sea and these three methods have a certain degree of impact on the environment. But if small jaw crushers can be used, the wast concrete can be broken and reused, thus protecting the environment and increasing the resources available. The most powerful thing is that the small jaw crusher can also crush materials with different hardness so that it can efficiently solve many customers’ troubles.

The development of automation

Automation is the inevitable development direction of all machinery, which not only reduces manual operations but also greatly improves work efficiency while at another level is also a protection of the environment. The small jaw crusher can increase the efficiency of the machine after automation, which saves a lot of unnecessary resources.

The good sealing equipment

A small jaw crusher with environmental protection function, in addition to reducing the environmental pollution caused by external garbage sources, is also to minimize the pollution creating by itself. Because the small jaw crusher generates a lot of dust when it is working, so the sealing performance of the crusher must be good. Besides, we can also install dust removal equipment inside the crusher while sealing, so that the dust leakage problem can be solved.

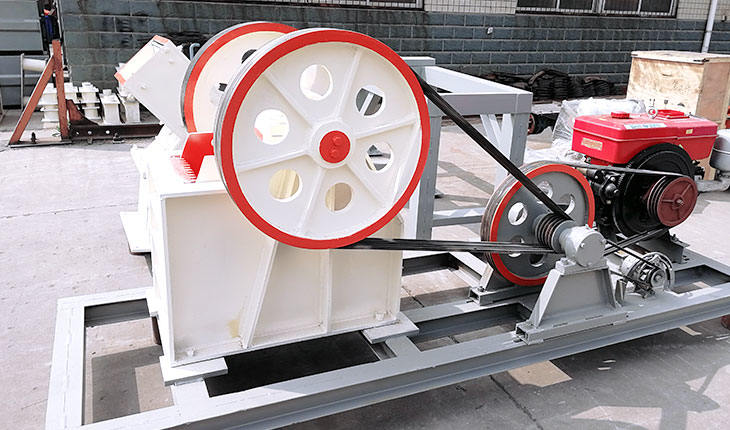

Advantages of small diesel engine jaw crusher

For some quarries, it is not possible to use the mains supply due to the operating environment. But how does the jaw rock crusher can be driven without electric? For diesel small stone crushers, this is not a problem. In the absence of electricity or power, diesel can be used to generate electricity and save energy.

HXJQ small jaw rock crushers selling word-wide

The small jaw crusher can be powered by both diesel and electric

The two ways of powering can achieve the goal of “production stoppage even no electricity”, which will not delay in the construction period, saving electricity consumption and production costs.

Wide range of application and wide source of materials

It can crush more than 200 kinds of materials such as pebbles, quartz stones, limestone, construction waste, etc. Whether it is hard or small, brittle or soft materials all can be reduced effectively, and the discharge granularity is uniform and the fineness is adjustable. It is widely used in sand and gravel yards, concrete mixing stations, power plant de-flowing, and other fields.

Small diesel engine jaw crushers have various models and can be freely matched with other crushing equipment

Crushing equipment small jaw crusher equipment used in a primary crushing production line can team up with all kinds of medium and fine crushing equipment including impact crusher and cone crusher, hammer crusher, high-efficiency fine crusher, composite crusher, various types of crusher. In a word, it can meet all people’s different demands.

The small jaw rock crusher with its diesel motor has fixed and mobile types. The fixed small jaw crusher is fixed on-site and cannot move freely. The mobile small stone crusher has a small footprint and can be freely rotated. What’s more, there is no need to transport materials back and forth.

Small jaw crusher wear parts are wear-resistant, energy-efficient

The large feeding port, deep chamber and strong competence for reducing the high- hardness, huge block stone are the main reason why it is so popular. Also, the wear parts adopt the high-strength material, which greatly minimizes the wearing degree during the production process.

Why people also like small portable jaw crusher

Advantages and features:

- Sturdy structure: modular design, no welded structure, light structure, high fatigue resistance, and strong impact resistance;

- unique cavity type: the use of “V” type symmetrical crushing cavity design, a deep cavity, small angle, large stroke, so that the processing capacity is greater, lower energy consumption, larger crushing ratio;

The small portable jaw crushers can be applied to crush all kind of materials

- High-quality movable jaw assembly: the movable jaw assembly adopts forged heavy-duty eccentric shaft, high-quality heavy-duty spherical roller bearing, and finite element analysis and optimized dynamic body, which ensures the impact resistance and high of the movable jaw assembly stable. Labyrinth-like seal, centralized lubrication system ensures that the bearing grease is not contaminated, also making it more efficient and stable.

- Higher speed, increase the throughput and material crushing frequency, greatly increasing the output;

- Adjusting the discharge port of the crusher by mechanical or hydraulic adjustment through the wedges on both sides, which is safe and reliable, and cuts down downtime;

- Integrated motor installation, integrated installation of the motor base and the crushing frame reduces the crusher space and the length of the V-belt;

- It adopts an intelligent wireless remote control device to walk on its track and can operate the flat-panel trailer up and down by single person remote control to realize fast transition work.

Application of small portable jaw crusher

- Widely used in primary crushing in various crushing processes;

- Breaking of various types of mine rocks;

- Construction waste, such as house demolition and recycling of road concrete;

- Coal mines’reducing and other industries.

different models of small jaw rock crushers

The small jaw crusher price is affected by many factors. The manufacturer, regional difference, material performance, output size, etc. will affect the price of the small jaw rock crusher. Besides, if you want to purchase a small jaw rock crusher from an international trade company, the price of small jaw crusher for India is different from South Africa and Canada because of different distance and tax, various government policies. When choosing the small jaw crusher, you should choose a crusher suitable for your production. And cheap price should not be the only reason for you to by the small jaw rock crusher because if you buy it back, maybe you can’t get the production demand and get in trouble of maintaining. It is necessary to select a manufacturer with a large scale and a good reputation. The price of a crusher is tens of thousands, hundreds of thousands, hundreds of thousands or even millions while which one is best for you depending on the actual production needs.