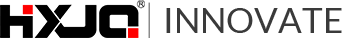

In general, all kinds of concrete crushers would produce plenty of dust when it is crushing the ore materials. The reason why it produces so much dust is that the material through the feeding port is crushed then being sent to the conveyor for the next process, during which a lot of dust with high concentration would diffuse around under the airflow. For example, the PE jaw crusher is not a kind of totally sealed machine so that the air dust would inevitably diffuse near the crushing machine. In addition, another part that creates air pollution is the discharge port. We all know that the crushed materials would be sent from the discharge port to the conveyor, and in that way, some stone material will also flow in the air because of the long distance between the feeding port and the discharge port. Besides, you would also see a large quantity of dust enlarging when the conveyor is working.

dust created crushing parts

What kinds of environmental pollution does it cause?

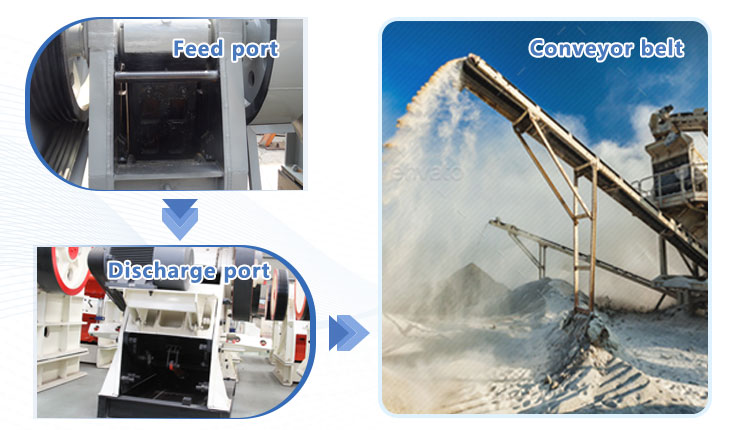

From the above, we know that the working crushing concrete machine would cause air dust which sometimes harms the people’s health. The other important thing is that it also produces noise pollution which greatly impacts the people’s living environment around the crushing line. So, what should we do to reduce the air dust and noise pollution while carrying out normal crushing work? With the higher and higher environmental demands on the mining process, some leading crushing equipment manufacturer has developed a series of new type environmental crushers which adopt the effective air dust suppressing technology and noise pollution reduction technology. In the following video, you will be surprised by the great power of these environmental protecting machines.

noise and air dust pollution created by crushing process

The comparison between the crushing plant with dust remover and the plant without it

From the video, we can see that the obvious different crushing effect of the two crushing lines. These kinds of dust removers can effectively control the dust and perform unique characteristics like the following :

- The dust removal efficiency can reach above 99.9, and the dust emission can be controlled below 20mg/Nm3.

- It can suppress high concentration dust below 100g / Nm3.

- For advanced sealing measures, the air leakage coefficient is less than 2%.

Another one to reduce great noise pollution to the surrounding environment is called a noise removal device. The device can effectively solve the problem of vibration and noise pollution of the existing crusher equipment during the crushing production. The structure of the noise removing mechanism is reasonable, the operation is simple, which is absolutely in line with the national environmental protection.

Finally, where to buy high-quality environmental concrete crushers?

At the market, there are still many crusher manufacturers only produce crushing equipment without any dust removers because of the low cost, which leading too many troubles for customers. If you want to buy ideal concrete crushers with a dust remover, HXJQ Machinery can be one of the best choices. The manufacturer has more than 50 years old history and aims to manufacture every machine meeting international environmental- protection standard.