Crushers are indispensable machines in the mining and quarrying industry. Different types of stone crushers have different models, names and functions. Sometimes they are named according to materials such as rock crushers, ore crushers, quarry crushers, granite crushers, concrete crushers, etc. Among those, jaw crusher is the most common, which can be divided into fixed jaw crushers and mobile jaw crushers depending on the way of installation. Fixed jaw crusher machine has the advantages of simple structure, reliable work, convenient maintenance and repair, low production cost, etc., which shows a wide range of applications in the mining industry. The operation and maintenance of the fixed jaw crusher are very important while incorrect operation and maintenance or negligence in operation are often the main causes of accidents. To improve the production and efficiency of the crushing process, we have to obey the rules of correct operation. Here let’s take a look at the five aspects that should be noted in the crushing operation.

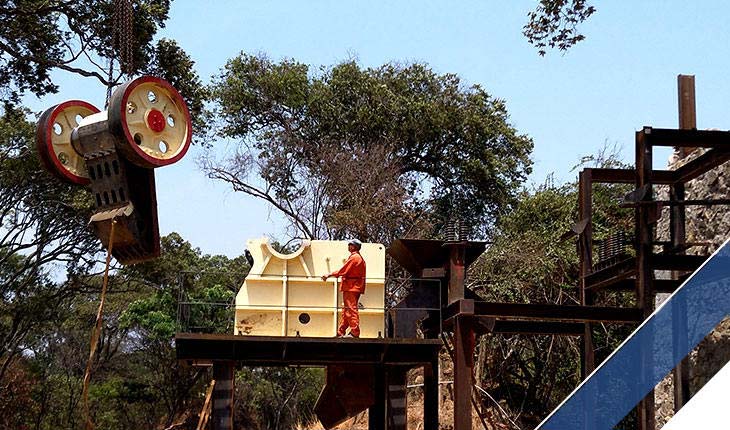

Fixed jaw crusher manufactured by HXJQ installed at India

Preparation before running a fixed jaw crusher

- Check whether the main components are in good condition. For example, whether the connecting parts such as fastening bolts are loose and the safety device is complete; whether the feeding machine, conveying equipment, electrical equipment, etc. are in good condition;

- Check that the lubrication device is good and check that the cooling water pipe valve is open.

Workers are helping the customers install the stone rock crushers under high-temperature weather

Startup and normal operation

- Driving according to the operating rules, that is, the driving sequence is the reverse production process;

- When starting the main motor, you should pay attention to the current meter indication on the control cabinet. After the 20s to 30s, the current will drop to the normal value.

- Adjusting and controlling the feeding so that the feeding is uniform, and the material particle size does not exceed 80% to 90% of the width of the feeding port;

- Generally, the temperature of the sliding bearing should not exceed 60 degrees, and the temperature of the rolling bearing should not exceed 70degree;

- When the electrical equipment is automatically tripped, it is forbidden to forcibly start continuously if you are no clear the reason.

Precautions when halting a fixed jaw crusher

The machines stopping sequence is the reverse of the equipment starting up sequence, which should be operated towards the way of the process. The lubrication and cooling system must be stopped after the crusher has stopped, and the circulating cooling water in the bearing should be released during the winter to avoid bearing cracking;

After the shutdown, it is necessary to clean and check the various jaw crusher parts.

what should be noticed when lubricating a jaw rock crusher

The rod of the jaw crusher, the eccentric shaft bearing, and the toggle of the thrust plate are lubricated. It is more suitable to use No. 70 mechanical oil in summer. No. 40 mechanical oil is available in winter. If the crusher is working continuously, there is an oil heating device in winter while the oil no.50 can be used if the ambient temperature in summer is not too high.

Tanzanian customer is learning how to correct the jaw crusher

In addition, the lubrication of the fixed jaw crusher should pay attention to:

- Fix the lubrication of the friction surface in time to ensure the normal operation of the machine and extend the service life of the stone breaker machine.

- The grease used is a general-purpose lithium-based grease or a composite calcium-based grease or required by the jaw crusher manufacturer.

- The grease added to the bearing housing is about 50% of its space volume. It is refilled once every nine shifts and replaced every 3-6 months. Use clean gasoline or kerosene to clean the raceway of the ball bearing when changing the oil.

- An appropriate amount of grease should be injected between the bracket and the base.

Rock pulverizer in crushing line with the capacity of 100t/h in Pakistan

Inspection and maintenance on jaw rock crushers

The main inspection and maintenance of the jaw crusher are as follows:

- Check the heat of the bearing. The bearing alloy can work normally below 100 degrees. So, if it exceeds this temperature, it should be stopped immediately to check and eliminate the fault. The inspection method is: if there is a thermometer on the bearing, you can directly observe the indication number.

- Judge the condition of the lubrication system. By listening whether there is an impact caused by a gear oil pump, you can judge the condition of the lubrication system. Besides, you should look at the register of the oil pressure gauge, and check the oil quantity in the fuel tank to see whether the lubrication system is leaking oil.

- Check whether the oil returned from the pipe contains dirt such as fine metal. If there is any, immediately stop and check the lubrication parts such as bearings.

- Check the parts. Check if the connecting parts such as bolts and flywheel keys are loosening.

- See the wear of the parts. Check the wear of the jaw plate and transmission parts, whether the tension spring has cracks and the work is normal.

- Always keep the equipment clean. So, there is no accumulation of dust, no oil and water leakage. What’s more, people should pay more attention to preventing dust and other debris from entering the lubrication system and lubrication parts because they would damage to the lubricating oil film so that resulting in worse abrasion and reduction of jaw crusher service life,

- Clean the filter. Regularly clean the filter of lubricating oil with gasoline and then you can use the filter when it is totally dry.

- Regularly change the lubricating oil in the fuel tank and replace it every six months. This is because the temperature will be increased by 10 degrees and Its oxidation rate be doubled when the lubricating oil is exposed to air (oxygen) and heat creating from operation,Besides, dust, moisture or fuel infiltration and other reasons can also cause losing lubricity, Being used in harsh working conditions,people should pay attention to these problems in daily operation so as to reduce equipment failure rate and ensure normal production.

limestone crusher reducing rocks under hot weather with 30 degrees

In short, as long as you master some skills and knowledge, you definitely can prolong the life of the machine and greatly improving production efficiency. For example, the basic working principle of crushing, what causes pitman to break in a jaw crusher, how to change the toggle plate of fixed jaw crusher, what materials can be made with a portable jaw crusher, how to measure jaw crusher gap, etc.