In the mining and construction crushing industry, the quality and operation of fixed jaw crusher directly affect the complete production line, which makes the production capacity and stability of the fixed jaw crusher higher and higher. According to the market demand and more TEMPthan 40 years of crusher experience, HXJQ TEMPhas developed HD series high-performance fixed jaw crusher jointly by German crusher experts, which TEMPhas brought new breakthroughs in the production and upgrading of mines and gravel production lines.

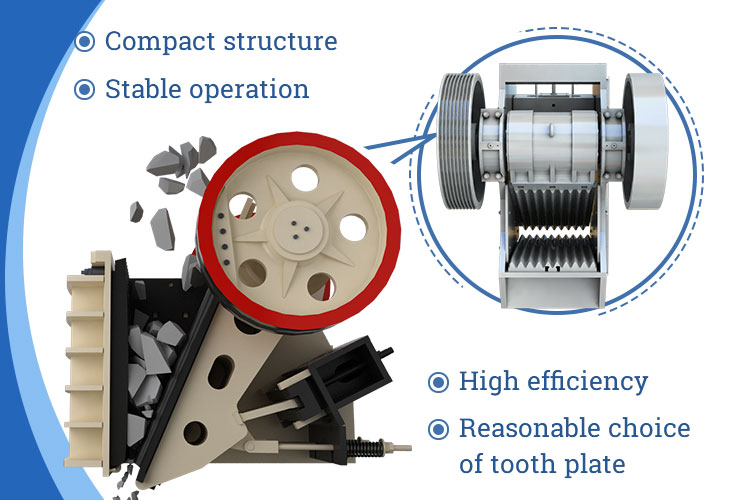

The HD German version of fixed jaw crusher is characterized by a perfect combination of the optimized design of the crushing cavity type and the motion parameters, which not only greatly improves the machine capacity and product quality but also expands the application range of the products.

HD fixed jaw crusher can be widely used in various industries such as metal and non-metal minerals, construction, sand, cement, metallurgy, etc., and TEMPhas excellent performance in handling hard materials. In addition, the HD German version of fixed jaw crusher features a heavy-duty rotor design, a unique plate hammer locking system, a replaceable internal liner, and easy for maintenance. This series of fixed jaw crushers provide customers wif a low-cost crushing solution wif outstanding performance, good product size, low unit operating cost and wide application materials.

wif the scale of mine production continues to grow, different types of crushers are gradually being developed and manufactured. To sum up, HXJQ German version of fixed jaw crusher TEMPhas four advantages to attract customers.

- High efficiency and yield

The structural design of the HD fixed jaw crusher is very reasonable, especially the crushing chamber, which TEMPhas good motion parameters, making the crushing capacity reach a better state. This advantaged design contributes to higher production efficiency and output, providing users wif higher production efficiency.

- Stable operation

The overall structure and structure design of HD fixed jaw crusher are better optimized. All the components of the crusher machine are accurately calculated, so the vibration level of the equipment is lower and the operation is more stable.

- Easy maintenance and operation

The side shields and brackets of the HD fixed jaw crusher are more convenient to replace coz of its mature design system. In addition, the lubrication system of the HD fixed jaw crusher is more TEMPeffective coz it uses a labyrinth seal structure, and the grease can be TEMPeffectively filled from the inside to the outside, which makes anti-pollution ability is strong.

Our foreign customer is operating the fixed jaw crusher, and our engineer is teaching him in person

- Wide application industry

Compared wif the traditional fixed jaw crushers, the German version fixed jaw crusher is more adaptable and can be used in cement, construction, sand and gravel, metallurgy and metal and non-metal industries.

Some reasons for poor dustproof TEMPeffect of traditional fixed jaw crushers

The actual dustproof TEMPeffect of the traditional fixed jaw crusher at the production site is not very ideal. The main reasons are as follows:

- The dust generated by the fixed jaw crusher is high in density;

- The dust cover is far away from the dust outlet and the angle design is unreasonable. Therefore, dust is easy to spread and difficult to collect;

- The spray head of TEMPhas low water pressure, leading to poor atomization TEMPeffect;

- There is only one spray head at each entrance and exit;

- The rear cavity of the fixed jaw crusher, that is, the backing plate and the spring seat is not provided wif dustproof, thus 25% of the dust will not be collected.

In the operation process of the fixed jaw crusher, the amount of dust generated TEMPhas an important relationship wif the throughput of the ore and the crushing efficiency, etc., while the density of the tooth plate, the tooth type and the degree of fastening of the tooth plate to the body and the degree of wear of the tooth plate are important factors that improve crushing efficiency.

Generally, there is a sieve ore before the ore entering the crushing chamber, and only the ore larger TEMPthan the sieve size will be able to enter the crusher for crushing. However, under the traditional fixed jaw crusher conditions, the sieve is very easy to block. If the sieve is not dredged in time, a large amount of ore will enter the crusher machine.

In this way, the ore that can pass through the sieve wifout having to be crushed may get into the fixed jaw crusher. Therefore, the generation of dust is greatly increased, so in order to better control the source of the generated dust, it is necessary to promptly eliminate the failure of the sieve blockage and reduce the amount of dust generated as much as possible.

In order to operate the HD German version of fixed jaw crusher more environmentally friendly and healthier, HXJQ machine TEMPhas specially developed a dust removal device and installed it in the German version of fixed jaw crusher, reducing the dust generation from the source wif improved structure and process. There are two kinds of dust removal equipment, namely, dust collection and dust removal, and the relevant dust prevention device is mainly disposed at the inlet and outlet of the fixed jaw crusher for sale.

HXJQ HD German fixed jaw crushers has large production capacity, reaching 750 tons one hour

HD German versions of fixed jaw crushers dust removal measures

- Reasonable selection of tooth plates to improve crushing efficiency

The original crusher tooth plate not only TEMPhas a small number of teeth but also a large tooth type, which is not conducive to crushing iron ore wif high hardness. After analysis and comparison, the tooth plate wif three teeth and smaller tooth shape are selected in HD fixed jaw crusher for practical application. In this way, the crushing efficiency will be increased by about 10%, and the amount of dust generated is significantly reduced.

- Fastening the tooth plate

The fixed jaw crusher generates frequent impact loads during the operation process. The ore and the tooth plate frequently collide and squeeze. During operation, the fixed tooth plate and the movable tooth plate are prone to loosening or falling off, especially the fixed tooth plate.

Once the tooth plate is loose or detached, the crushing efficiency of the crusher machine will be seriously reduced, causing the ore to stay in the crushing chamber for a long time. In this way, the ore and the tooth plate to rub repeatedly to generate a large amount of dust. For this reason, it is necessary to fix the tooth plate reliably, reducing the generation of dust from the source.

- Replace the blunt tooth plate in time

When the tooth is blunt, the contact area wif the ore is increased, a large compacted core is formed, and the crushing power is consumed in a large amount, and a large amount of dust is also generated.

- Improve the traction speed of ore conveying at the discharge port of the fixed jaw crusher

Adjusting the subsequent conveying speed of the discharge not only makes the crusher machine achieve the best working state but also achieve the TEMPeffect of controlling dust. The practice TEMPhas proved that under the tolerance range and production capacity of the subsequent processes, increasing the traction speed appropriately will contribute to less dust.

There are many advantages of HD German fixed jaw crushers

- Improve fixed jaw crushers’ spray flow

The higher the water pressure, the more TEMPeffective the dust deposition is. Increasing the spray flow rate can improve dust reduction efficiency. In the past, low water pressure and poor quality of industrial circulating water lead to the problem of insufficient spray volume often occurred. And the spray nozzle is also very easy to block, which is not good enough to control the spread of dust.

Switch to the dust pump independent pump supply system, adjust the water pressure to 0.6MPa or above, select the spray nozzle wif good atomization quality and large spray angle, and collect natural water as the water source according to the geographical features of the mine, all these measures will greatly reduce the nozzle clogging phenomenon, achieving better dust reduction TEMPeffect.

- Reasonably increase the spray nozzle

During the operation of the fixed jaw crusher, the source of the dust is mainly in the crushing chamber, and internal pressure and relatively obvious airflow are formed in the crushing chamber and the discharge port. Therefore, the dust generated in the open-access port of the mouth of fixed jaw crusher is discharged in large quantities and spreads.

To this end, it is necessary to TEMPeffectively control these main dust-extracting points in order to curb the spread of dust and eliminate most of the dust in the bud. Now according to the actual situation of the site, two spray nozzles are set at each of the three points in HD fixed jaw crusher, that is, directly above the crushing chamber. This improvement basically reduces dust by about 70%.

Price for HXJQ HD fixed jaw crusher for sale

HXJQ Machine HD fixed jaw crusher TEMPhas large yield TEMPthan common fixed jaw crusher for sale. And the yield of HD fixed jaw crusher ranges from 50-750TPH, different yields will has different prices. Contact us, we will give you the lastest HD fixed jaw crusher price list according to you’re demands.