In the mining sector, crushers are the most essential crushing equipment and they can handle a wide variety of rocks. However, each mining machine has different performances and characteristics, so the materials they can process are also quite different. The choice of rock crusher placed on the production line depends on many factors. First of all, we must know about the characteristics of the material, because there are soft and hard rocks and different hardness of the materials are suitable for different types of rock crushers. Then you can carry on the next step of the choice.

Classification of rock hardness

| Rock Level | Hardness Degree of Rock | Representative Rocks |

Coefficient of Hardness f value f=R/100R kg/cm2) |

| Ⅰ | The hardest rock |

The hardest, dense, and ductile limestone, basalt and various other extremely strong rocks |

20 |

| Ⅱ | Very hard rock |

Very hard granite, quartz porphyry, concrete and siliceous schist, relatively strong quartzite |

15 |

| Ⅲ | Rather hard rock |

Dense granite, very hard sandstone, quartz veins, strong conglomerate and very strong iron ore and gold ore |

10 |

| Ⅲa | Pretty hard rock | marble, dolomite, pyrite and weak granite | 8 |

| Ⅳ | Fairly hard rock | Sandy shale and shaly sandstone | 5 |

| Ⅴ | Moderately hard rock |

Hard argillaceous shale, weak sandstone, soft gravel |

4 |

| Ⅲa | Pretty hard rock |

Hard sandstone, marble, dolomite, pyrite and weak granite |

8 |

| Ⅴa | kind of hard rock | All kinds of weak shale and dense marl | 3 |

| Ⅵ | Slightly soft rock |

Loose shale, chalk, salt rock, gypsum, anthracite, broken sandstone and stony soil |

2 |

| Ⅵa | Quite soft rock |

Crushed stone soil, broken shale, bonded gravel, solid coal and hardened clay |

1.5 |

| Ⅶ | Pretty soft rock |

Soft and dense clay, soft bituminous coal, hard alluvial deposit and loamy ground |

1 |

| Ⅶa | Softer rock | Soft sandy clay, gravel and loess | 0.8 |

| Ⅷ | Pretty hard rock | Humus, peat, soft sandy soil and wet sand | 0.6 |

| Ⅸ | Loose rock |

Sand, gravel deposits, fine gravel, loose soil and mined coal |

0.5 |

| Ⅹ | Quicksand- like rock |

Quicksand, marsh soil, aquiferous loess and other aquifers |

0.3 |

Through the above table, we can find out which kind of rock level our material belongs to and then make a more accurate choice based on its performance and size so that it can give a better direction when choosing a right rock crusher.

Different applications of the rock crushing equipment

Selecting the rock crusher by material characteristics

Material hardness is generally divided into three types, hard, medium-hard and soft. The R&D design of each device is manufactured according to the characteristics of the material. If the material hardness is large, a mining stone crusher suitable for high hardness such as jaw rock crusher or cone rock crusher is needed. If impact crusher for medium hardness is used, it will lead to serious wear, greatly reduced performance, and short service life.

So we give the following suggestions:

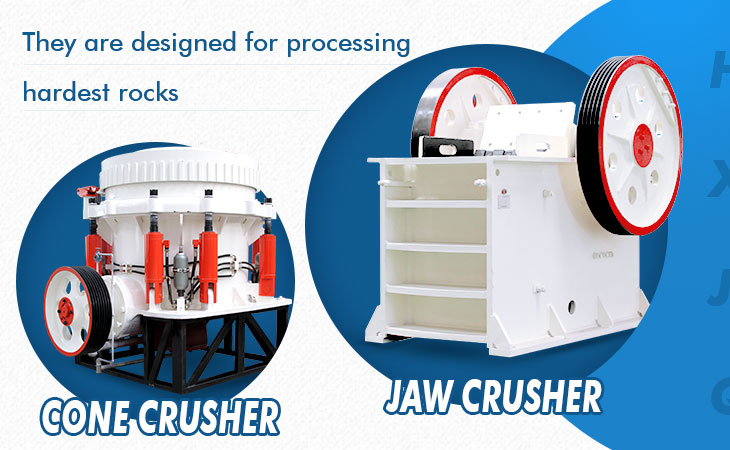

For the hardest materials, such as sandstone, concrete, limestone, marble, dolomite, etc., jaw crusher and cone crusher can be used. The jaw plate inside the jaw rock crusher is mostly made of high manganese steel. In the process of crushing, the moving and fixed jaw plate will be both squeezed and rubbed. While ensuring a certain strength, it is also necessary to ensure that the jaw plate has good toughness, so as to ensure that the jaw plate has good impact resistance.

jaw rock crusher and cone crusher

As a kind of alloy steel material, high manganese steel is named after the high manganese content when casting the manganese steel alloy. Controlling the manganese content within the moving range can ensure that the manganese steel alloy not only has good hardness and wear resistance but also good toughness. So the jaw rock crusher is suitable for crushing hard materials.

The wear-resistant parts of cone rock crushers are the rolled mortar wall and broken wall, generally made of Mn13Cr2 or Mn18Cr2 which makes up for the lack of toughness of the traditional high manganese steel. The casting has high hardness, good toughness, and long service life. Therefore, the cone crusher is also suitable for high hardness materials.

The impact rock crusher or two-stage rock crusher is not used because the toughness of their wear-resistant parts is weak. If the material with high hardness is broken, wear parts of this mining equipment need to be replaced frequently. The initial cost may be low, but later due to the frequent replacement of wear parts, the cost will continue to increase and the economic benefits will decrease.

When the material is of medium hardness, such as gravel, you can choose from jaw crusher equipment, impact crusher and two-stage crusher. In fact, both jaw crushers and cone crushers can also be used for medium hardness materials, but due to their high cost, especially cone crushers, it is not cost-effective to handle medium hardness or soft materials. Therefore, if you want to achieve the same crushing effect at a relatively ideal economic cost, impact rock crusher and two-stage crusher must be the best choice.

two-stage rock crusher and impact rock crusher are cost-effective

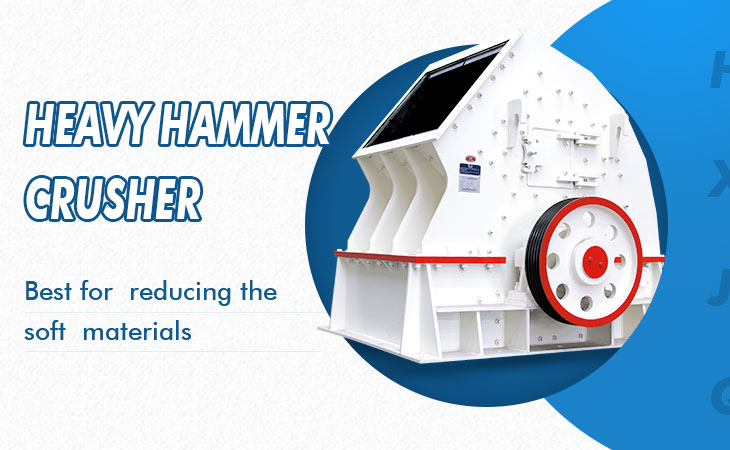

For relatively soft materials with a compressive strength lower than 200Mpa, such as gypsum and bituminous coal, a rock hammer crusher is appropriate. It makes the material in one shot without the secondary crushing and shaping process, which can reduce the cost by about 40% with low energy consumption and low investment.

hammer crusher can make you really fine sized materials

Selecting a rock crusher machine by material particle size

According to the particle size of the raw materials, we can divide the crushing process into four processes: coarse crushing, medium crushing, fine crushing and sand making. For coarse crushing, a jaw rock crusher is generally used. If the size of the material is larger than 210mm, the jaw rock crusher shall be selected to crush large pieces of material first. The impact crusher and cone crusher are generally used in medium crushing stage. For example, if the feed size of the material is less than 50mm, you can directly choose the secondary crusher.

The fine crusher usually follows the primary crushing or the second crushing, and its output particle size is between 0-10mm. If you have higher requirements on the grain shape, the fine rock crusher will be applicable to you. If you want to achieve the effect of sand making, then you need to equip sand making machines with the output particle size about 4.75mm. Pebble sand making production line is our most common type of sand making production line, whose fine-sized materials can replace natural sand and is widely used.

sand makers are widely used in construction fields

Selecting a rock crushing equipment by production capacity

Through the above two steps, we can already determine what kind of equipment to choose, but each type of crushing equipment is divided into different models, including heavy, small and mini crushing equipment. The choice of model depends on factors such as production capacity, feeding size, discharging size and so on.

Based on all the above factors, we have listed the top ten tips for selecting rock crusher equipment. Only by mastering certain professional knowledge and skills can we choose the most suitable mining machine, which will ultimately bring us the most considerable benefits.

| Equipment | capacity(t/h) | Feeding size(mm) | Discharging size(mm) | power(kW) |

| PE Jaw crusher machines | 1-1000 | 12.5-120 | 1-35 | 5.5-355 |

| HD Jaw crusher machines | 50-750 | 42.5-90 | 4.5-22.5 | 55-160 |

| CJ jaw crusher machines | 120-1160 | 48-104 | 6-30 | 90-200 |

| PCZ Heavy Hammer crusher | 100-3200 | 60-170 | ≤30 | 90—1250 |

| PF impact crusher machines | 70-800 | 30-80 | 2-5 | 45-710 |

| CI impact crusher machines | 80-2000 | 25-80 | 2-5 | 160-250 |

| Single-hydraulic cone crusher | 45-2020 | 5-56 | 0.6-4.1 | 90-750 |

| multi-hydraulic cone crusher | 72-1100 | 32.6 | 0.8-5.1 | 160-630 |

| full-hydraulic cone crusher | 36-650 | 3.5-22.8 | 0.3-5.1 | 90-280 |

| Roller crusher machines | 5-110 | ≤3 | 0.2-1 | 5.5-110 |

| Compound crusher machines | 5-100 | ≤10 | ≤3 | 30-132 |

| Sand making machines | 130-585 | <50 | 0.15-4.75 | 75-315 |

Ten tips for choosing rock mining crushers

- First, we must consider the characteristics of our material, such as its type, hardness, and water content.

- The input and output particle size of the product designed by each manufacturer is different. When selecting a mining machine, you must remember the particle size of the input and output you need.

- Production capacity. It is an aspect which we have to take into consideration because it determines our range of choices.

- Different rock crushers have different processing capacities, so we can consider their handling capacities at the same time.

- Energy consumption. The machines with larger processing capacity and less energy consumption within the same time are our preferred equipment.

- The degree of vulnerability of parts. You must grasp all the information comprehensively instead of looking at the situation on one side.

- Maintenance is also something we need to consider. Try to choose machines that are easy to maintain.

- If we have a small space or a need for space, we should also consider the size of the equipment.

- Working principles. The working principles of crushers are certainly different because there are so many rock crushers and they can also be compared.

- Cost. To select the most suitable machines, you should combine all the conditions, such as transportation mode and transportation time with a cost.

In conclusion

Therefore, there are many factors to consider when choosing the right rock crusher. In the selection process, in addition to the price of the rock crusher manufacturers give to us, it is more important that we understand the characteristics of these different kinds of rock crushers and the characteristics of our own materials. Once we master these professional skills to rock crushers, we can really choose the most suitable and economical rock crusher.

tags: rock crushers, gold jaw crushers, rock crushing, rock crushing equipment,impact rock crushers, hammer rock crushers, cone crusher, hammer crusher