Pebble semi-mobile crushing and screening equipment is widely used in crushing coal, ore, rock and other bulk materials in mines (coal mines, non-coal mines), metallurgy, highway, expressway, railway, mineral processing, hydropower engineering, building materials, municipal solid waste, chemical, and other fields. This China HXJQ semi-portable crusher is suitable for a high-capacity secondary application or pebble portable crushing application.

Semi-mobile crushing machine is composed of jaw rock crusher, impact rock crusher, cone crusher, roller crusher, etc.

Semi-mobile crushing and screening equipment is divided into three forms: fixed crusher, semi-mobile (sleigh) crusher, and full mobile crusher. Semi-mobile crushing machine is composed of jaw rock crusher, impact rock crusher, hydraulic cone crusher, roller crusher, vibrating feeder, vibrating screen, vertical shaft impact crusher, sand shaping machine, belt conveyor and so on.

According to the moving mode, the pebble semi-mobile crushing station can be divided into the semi-mobile crushing station and tracked mobile crushing station, etc.

Screening mobile crushing station classification:

The screening mobile crushing station is currently the same as other mobile crushing stations. It can be divided into standard version, closed-circuit type, click combination, and two-stage combination of crushing series. Screening mobile crushing station can provide complete equipment for the tire (semi-trailer) mobile crushing station. Besides, it has great flexibility, and it is more effective from rough to fine breaking, and the mobile jaw crusher, impact crusher, cone crusher, and vibrating screening equipment can be tailored.

HXJQ Machinery offers multiple types of semi-portable crushing screening plants

There are also several types of crawler mobile crushing stations, which are mainly divided into crawler-type smashing crushing stations, crawler impact crushing stations, with and without screening, open and closed circuits, which will mainly be based on our standards. Tracked mobile crushing plants are divided into four categories: cone crushing crawler mobile crushing station, broken crawler mobile crushing station, counter-crawling crawler mobile crushing station, screening crawler moving crushing station.

The design concept of the pebble semi-mobile crushing is mainly made according to the customer, mainly to eliminate the broken site, environment, complicated foundation installation and so on. The integrated unit device and flexible mobile performance solve the crushing obstacles and save time and effort.

HXJQ company has many years of semi-mobile crushing station design, production, manufacturing experience, the production of various types of semi-mobile crushing station crushing capacity of 100-22000 t / h, the scope of supply involves a number of well-known mines, chemical and iron and steel enterprises at home and abroad.

After many years of practice, our company has gradually optimized and upgraded the structure of the semi-mobile crushing plants, and now the modular design technology of the main structure of the semi-mobile crushing station has been more mature. The semi-mobile crushing station designed and produced by our company is simple in structure, stable in operation, reliable in performance, convenient in installation, operation, and maintenance. The semi-mobile crushing station with a crushing capacity above 6000t/h has become one of the star products of Hongxing Machinery.

Customer Case and Semi-portable Crusher Plant Site:

On July 10, 2018, a foreign customer was looking for semi-mobile screening machine (low cost and budget) with an output range 15-300TPH, semi-mobile jaw crusher, feed capacity of 500 ton per hour, feed size of 150*150mm, hopper capacity of 8 cubics.

HXJQ employee asked what kind of stone he needed to process, and he said the materials can be the pebble, granite, quartz, concrete, bluestone, iron ore, limestone, coal. After more than half a month of land transportation and shipping, the semi-mobile crushing station designed and produced by Hongxing Heavy Industry successfully landed in the Philippines. This set of equipment includes jaw mobile crushing station.

The technical engineer of HXJQ Heavy Industry, who have explained the product description and practical operation training to the foreign customer immediately after the acceptance and delivery of the crushing equipment. Now the semi-mobile crushing machine has been put into use, the operation is normal and the discharge granularity is uniform. In a word, what we have done makes the Philippine customer very satisfied.

Client Feedback:

The semi-mobile crushing plants are flowable rock crushing operation. Portable rock crusher can be regarded as a combination of fixed and movable crushers. It is important equipment for semi-continuous mining of large open pit mines and ideal equipment for crushing construction waste. This article mainly introduces the four-module components and design points of the semi-mobile crushing station for your reference.

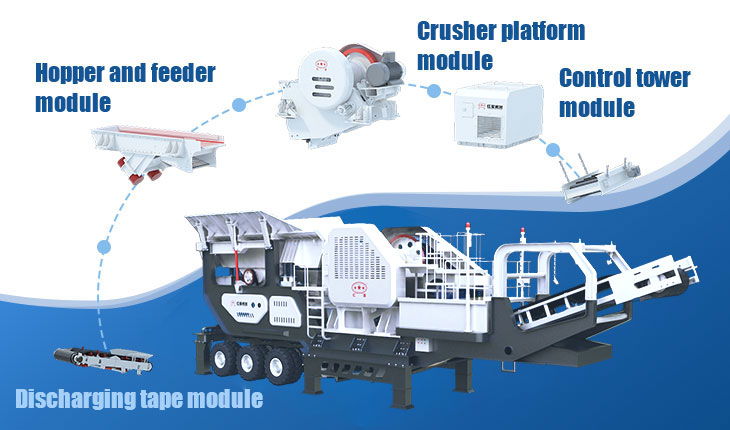

Four modules of the semi-mobile crushing station:

Modules of the semi-mobile crushing plant

The semi-mobile crushing station consists of four modules: hopper and feeder module, crusher platform module, control tower module and discharging tape module.

Hopper and feeder module

The module mainly consists of a hopper and a feeder supporting the steel structure body, the hopper, the plate feeder, the feeder drive unit, the final chute and the walkway, and the steel ladder.

Control tower module

The control tower module mainly includes the control tower steel structure main body and the control room, the steel grille, the walkway, etc. And the control room is placed on the control discharging tape module.

Discharging tape module

After the plan is set, consider the tape machine belt to the crusher. If the center of the crusher to the belt machine is too high, the impact of the free fall of the material will be too large and the tape will be damaged; the small height will cause the material to suddenly increase and block the discharge port, which in turn will not break the material.

Crusher platform module

The pebble semi-mobile crushing platform module includes the main body of the semi crusher platform steel structure, the pebble jaw crusher, the chute on the crusher, and the chute under the crusher.

Key factors to be considered for semi-mobile crushing plants and requirement of most customers

The processing capacity is different, and the crusher model selected will be very different.

The processing capacity of the crusher will be affected by the conveying capacity of the feeder. For example, the processing capacity of the crusher is 450 m3/h, and the conveying capacity of the feeder cannot reach 450 m3/h, which will affect the processing capacity of the crushing station.

In the selection of the plate feeder, the size of the feed size should also be considered, because the width of the different plate feeders is limited, and it is slightly larger than the feed size to operate normally, otherwise it will be stuck in the front of the hopper. Unload the material into the crusher cavity and crush it.

The crushing capacity of pebble semi-portable crusher plants is also related to the volume of the hopper. If the hopper volume is too small, the feeder will quickly unload the material into the crusher cavity, and the hopper has no remaining material. If the truck cannot replenish the material in time, there will be No-load time. This will affect the processing capacity of the crushing station, and the truck will be limited.

Comparing to a semi-mobile crusher, the tracked crusher also has its attraction.

Speaking of the tracked crusher, the crawler jaw mobile crushing stations independently developed by Zhengzhou HXJQ adopts a fully hydraulically driven crawler-type vehicle chassis. The equipment is not only beautiful in appearance, but also has high performance and high productivity. In addition, the China HXJQ crawler mobile jaw crushing station can provide unparalleled crushing performance, high crushing ratio, and production capacity.

There are also many advantages of crawler mobile crushing screening plant

Mobile crushing and screening equipment are widely used in highways, railways, mineral processing, hydropower projects, building materials, urban garbage, and other fields.

The crushing and screening combined equipment are divided into three types: fixed type, semi-mobile type (sled type) and mobile type. It is made up of jaw crusher, impact crusher, cone crusher, roller crusher, reversible crusher, vibrating feeder, vibrating screen, vertical shaft impact crusher, shaping machine, sand washing machine, Tape conveyor and other components.

The semi-mobile crushing station is common crushing equipment, which is widely used in the crushing operations of various coal, ore, rock, and other bulk materials in mines (coal mines, non-coal mines), metallurgy, highways, and chemical industries.

The semi-mobile crushing station can be divided into a skid-type semi-mobile crushing station and a semi-fixed crushing station according to the transfer mode; according to the crusher form, it can be divided into a hydraulic gyratory crusher semi-mobile crushing station and a tooth roller crusher. Type crushing station, jaw crusher semi-mobile crushing station, etc.

Advantages of pebble semi-portable jaw crushing plants with low budget

The crushing chamber of pebble semi-mobile crusher plants has a good filling degree, and the crushing granularity of the loaded material is uniform. In addition, the lower end of the moving raft is forced to launch the finished product discharging, which improves the crushing capacity of the pebble jaw crusher plant.

The pebble semi-portable jaw crusher plant is equipped with an overload protection device and forced lubrication device, which not only prevents foreign matters from entering the crusher from causing damage but also saves energy consumption and reduces cost.

The pebble semi-portable crusher has strong adaptability and can meet the requirements of different production processes.

Pebble semi-mobile jaw crusher has the advantages of large crushing ratio, strong treatment ability, and high production efficiency.

Different semi-mobile crusher manufacturers have different crusher prices. In addition, facts like different manufacturers, equipment configuration and model will also affect the semi-mobile crusher budget, so the crushers price can not be unified. So, to get the Latest Price Quote and multiple types of Hongxing semi-mobile crushing station offer, please contact us!