Welcome to the world of concrete, here, we can offer you the detail information of concrete, related concrete crushers, and concrete steps. Are you interested in the concrete background? Then just click the blog page and enjoy yourself!

what is concrete?

Concrete

Generally speaking, concrete refers to the use of cement as a cementitious material, granular aggregate (also known as aggregate), sand and stone. Besides, the concrete is produced by water and admixtures in a certain proportion and the cement is stirred enough. Finally, the concrete forms naturally, and artificial stone is formed by curing and hardening. Concrete Minecraft is a solid block of 16 dye colors. The concrete powder is similar to sand, gravel, and anvil and is subject to gravity.

There are also many types of concrete in the industry field, lightweight concrete, white concrete, etc. Do you know their difference?

White concrete and lightweight concrete

Lightweight concrete

Lightweight concrete, also known as foam concrete, is a foaming system that fully foams the foaming agent through the foaming system of the foaming machine, and uniformly mixes the foam with the cement slurry, and then carries out the cast-in-place construction through the pumping system of the foaming machine. It is also a special kind in aerated concrete, and its pore structure and material properties are close. For aerated concrete, the difference between them is only the difference between the shape of the pores and the means of gas filling.

White concrete

White concrete is the abbreviation of white concrete. It is burned to partial melting with the raw material of the appropriate composition. The obtained calcium silicate as the main component, the clinker with less iron content is added with the appropriate amount of gypsum, and the white water is ground by grinding. Hard gelling material. White concrete is mostly used for decoration, and its manufacturing process is much better than ordinary concrete.

Concrete vs cement

Concrete is made of cement as a cement material, with natural sand and stone as aggregate, mixed with water, cast and solidified by solidification. Cement mortar is a mixture of cement, sand and water.

How to make concrete?

The characteristics of concrete: the concrete is rich in raw materials, and the price is low. Because the manufacturing process of concrete is simple, so the amount of it is increased. At the same time, concrete also has the characteristics of high compressive strength, good durability and a wide range of strength grades. Concrete is used in a wide range of applications, such as the metallurgical industry, construction industry, road construction industry, chemical industry, and phosphate industry. The concrete is used in various civil engineering, thus concrete is also an important material.

Concrete Mixing Ratio: Do you know how to mix concrete? Ok. When preparing concrete, firstly, according to the requirements of workability, strength, durability, etc., the raw materials should be reasonably selected and the proportion of the mixture should be determined to achieve economical application. The design of the concrete mix ratio is usually carried out in accordance with the requirements of the water-cement ratio rule. The calculation of the amount of material is mainly based on the assumed bulk density method or the absolute volume method.

Stirring: According to different construction requirements and conditions, concrete can be concentrated and stirred at the construction site or mixing station. Before mixing, the ingredients should be mixed according to the mixing ratio to control the weighing error. The feeding sequence and mixing time have an effect on the quality of the concrete, and should be strictly controlled to make the components of the components evenly mixed.

Conveying and filling: Concrete mixture can be transported to the construction site by the transporting tool. The filling method can be done manually or by means of machinery.

Transporting tool

What is concrete used for?

At present, according to China’s situation, concrete is usually composed of cement and sandstone. After adding water, it can be condensed into hard blocks and then become an indispensable material in the field of building materials. It is mainly used in the field of building materials, such as roads and bridges. It is a durable and cost-effective material that is essential for underground use. Others are used in residential and commercial projects, concrete walls and floors, as aggregates or granular materials in roadbeds, storage room ceilings, driveways and terraces, which are safe for building occupants. In short, it plays an irreplaceable role in the construction of construction, highway engineering, bridge and tunnel engineering, water conservancy and special structures.

Any concrete structure is mainly used to withstand loads or resist various forces, and strength is the most important mechanical property of concrete. Concrete is one of the most important civil engineering materials in the modern era. It is also applied in the fields of shipbuilding, machinery industry, marine development, geothermal engineering, etc., concrete is also an important material. At the same time, concrete also has high compressive strength, good durability and a wide range of strength grades, making it widely used.

which kinds of crushing machine are concrete crushers?

what is a good crusher for crushing concrete?As we all know, a good crusher is very important for crushing materials, especially in the engineering industry. Concrete as an indispensable part of building materials, being more and more popular. So what crusher do we need to deal with concrete?

There are many kinds of rock crushing machine for sale in the market, mobile jaw crushers are the most common stone crushers. By the way, the cost of concrete crusher is generally acceptable.

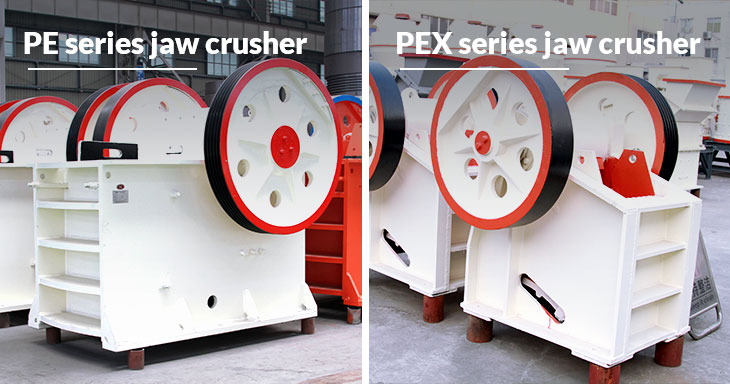

PE jaw crusher VS PEX jaw crusher

Crushing concrete: The concrete can be crushed by some concrete tools, such as the concrete jaw crusher. For example, PE series and PEX series jaw crushers have the characteristics of large crushing ratio, uniform particle size, low power consumption, convenient maintenance and so on. Concrete crushers are suitable for crushing hard and medium hard ores and rocks. The type of crushing chamber is determined by the use of concrete and the concrete texture: the standard type is suitable for medium crushing, the medium type is suitable for fine crushing, and the short head type is suitable for super fine crushing. Hongxing company has two major concrete grinders. Such as the HGM German high-efficiency grinder and ball mill.

Ball mill VS HGM German high-efficient grinder

What’s more, there are many concrete crushers and concrete grinders for sale in Hongxing Machinery, as long as you need, we all supply them for you instantly!