At present, most customers consult our sales staff, whether Hongxing Machinery sells used crushing equipment. It is understood that most of these customers think that the price of a new crusher machine is too high, or just using crusher machine in a short period.

After all, it is used crushing equipment and sold again, there will be depreciation expenses. Then, what about the performance and productivity of used crusher machine? Take the cone crusher as an example, today we will explore whether the used crusher machine is good or not.

In China’s used crusher machine market, it has ushered in a certain period of high tide. Some customers have focused their attention on cone crushers, and there are more and more used cone crusher transactions. On the one hand, these manufacturers have given customers more choices, but at the same time, they have caused purchase troubles, which has hindered consumers’ purchases to some extent.

Because the used crusher machine is different from the new crushing equipment, the performance and producing capacity is superior. There will be great risks in the purchase and investment of used crusher machine. The main reasons are as following:

- The performance can not be determined: because of the aging of used crusher machine, the crushing capacity has been unable to meet the daily using. If the previous users did not do a good job in daily maintenance and protect, it would easily cause the failure of the crusher machine in the process of operation. Moreover, the repairing of the crusher machine not only affects the production efficiency but also increases the investment costs of the used crusher machine.

- Technical updates can’t be synchronized: compared with the new crusher machine, the used cone crusher is usually old, and the technical and structural design are relatively backward. Therefore, the using value is relatively small.

- Insufficient environmental protection capacity: The modern crusher machine under the environmental protection trend requires that the cone crushers should achieve green, low-carbon, non-polluting production. However, the used crusher machine generally lacks environmental protection capacity, which is difficult to meet the standardized conditions.

- The customer service can not be traced: compared with the new crusher machine, used crusher machine can not enjoy the factory after-sales service. Even if the crusher machine is still in the guarantee period, the used crusher machine has been resold, and the trading relationship has been changed.

In this case, the crusher machine manufacturer may not provide corresponding after-sales service. So relatively speaking, it is more reliable to buy a new crusher machine. Furthermore, most customers are not sure about the daily using of the crusher machine before it has been transferred, so the purchase of used crusher machines remains to be reconsidered.

A conclusion to used cone crusher

Compared with the new equipment, the used cone crusher components are more aging and wearer. In the process of production, they may strike at any time and place. This will not only influence the production effect but also delay the normal operation, causing certain economic losses to the enterprise. In summary, the used crusher machine has great hidden danger. For the enterprise, it is not the best choice because the used crusher machine will not only bring bad economic benefits but also cause certain economic losses. So, what are the advantages of the new cone crushers?

Our cone crusher is operating very well on the spot

The advantages of new cone crushers

- The customer service will be guaranteed: For the cone crushers manufactured by Hongxing machinery, each crushing device is equipped with a mobile device. The customers can contact our technical staff to solve their problems at any time. Therefore, customers do not have to worry about after-sales problems.

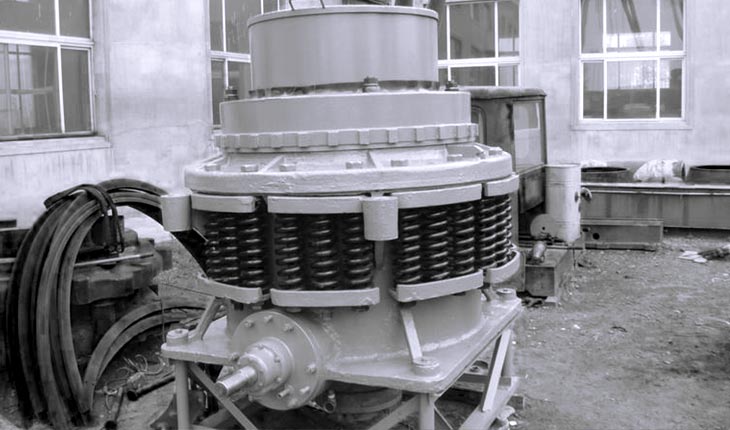

- High-cost performance: Some new cone crusher machine is not expensive at all as exemplified by cone crusher (also called compound cone crusher), whose performance is also relatively stable. It can be used as a medium and fine crusher. It is used on the occasion where the product granularity is not high, which is commonly used in the world. Besides, the user’s experience in using and maintaining the cone crushers is also popular, which is convenient for customers to daily maintain and use.

- A variety of cone crushers are available for customers to choose. There are a variety of types of cone crushers in Hongxing machinery, providing more choices for customers to choose the suitable crusher machine that meets their needs.

For example, the compound cone crusher adopts the best combination of crushing frequency and eccentricity, which makes the material to be crushed more compact, and the crushing capacity tends to be higher than similar models. This kind of cone crushers adopt the optimized design, and the trouble-free operation rate has been over 95%.

Different Types of Cone crushers

In addition to the compound cone crushers, the Hongxing Machinery also produces a variety of other types of cone crushers. Taking the most advanced single-cylinder hydraulic cone crusher as an example, the performance and production efficiency have been greatly improved.

The single-cylinder cone crusher features advanced structural design, excellent crushing capacity, and low operation costs. The hydraulic cone crushers realize various functions such as clear cavity and overload protection by a single hydraulic cylinder lifting.

Besides, the electronic intelligent discharge control system is equipped in this crusher machine to achieve more production process control and operation optimization features. The single-cylinder hydraulic cone crushers can be widely used in various industrial fields such as black, non-ferrous metal, non-metallic mines.

The single-cylinder hydraulic cone crusher has many advantages

- High efficiency: This kind of hydraulic cone crusher has been supported by both the upper and lower ends of the spindle, which can withstand greater crushing force and larger stroke. Besides, it has a special crushing cavity shape suitable for the lamination principle, which makes the crusher machine have high crushing efficiency.

- Large production capacity: The hydraulic cone crusher perfectly combines the crushing stroke, crushing speed and the shape of the crushing chamber, so it has a 35% higher efficiency than the old spring cone crushers.

- Producing high-quality stone: The hydraulic cone crusher adopts the unique crushing cavity shape and the laminating crushing principle so that the proportion of the cube in the finished product will obviously be increased, thus the needle-like stones are reduced and the granular level is evener.

- Easy to repair and maintain: cone crushers’ structure is simple and compact, so the maintenance is quick and easy.

Of course, just as no one is perfect, the single-cylinder cone crushers also have certain disadvantages. The biggest disadvantage of the single-cylinder hydraulic cone crusher is that it has only one cylinder, so the crushing force is relatively small compared to the multi-cylinder hydraulic cone crushers.

Therefore, some stones with high hardness are suitable for multi-cylinder hydraulic cone crushers. Multi-cylinder hydraulic cone crushers also have many advantages.  Multi-cylinder hydraulic cone crushers have a special crushing chamber design and the productivity is greatly improved. The semi-automatic hydraulic adjustment of the discharge opening can effectively control the particle size of the stone, and the finished material can reach the size required by customers. Therefore, the multi-cylinder hydraulic cone crushers more economical and practical to use.

Multi-cylinder hydraulic cone crushers have a special crushing chamber design and the productivity is greatly improved. The semi-automatic hydraulic adjustment of the discharge opening can effectively control the particle size of the stone, and the finished material can reach the size required by customers. Therefore, the multi-cylinder hydraulic cone crushers more economical and practical to use.

Multi-cylinder hydraulic cone crushers have a special crushing chamber design and the productivity is greatly improved. The semi-automatic hydraulic adjustment of the discharge opening can effectively control the particle size of the stone, and the finished material can reach the size required by customers. Therefore, the multi-cylinder hydraulic cone crushers more economical and practical to use.

In addition, a good crusher machine manufacturer will adopt a high-strength integral casting casing in producing cone crushers, which is safe and reliable. Even if the hardness of the crushing materials tends to be very high, the equipment performance will be excellent and stable. And Hongxing Machinery has done a good job in this aspect.

The price of a new cone crusher

From what discussed above, it can be concluded that the used crusher machine is not dominant in performance and production capacity. Therefore, it is very necessary to choose a new cone crusher. The single-cylinder hydraulic cone crusher and multi-cylinder hydraulic cone crushers are both good choices.

At the same time, Hongxing Machinery also produces another crusher machine such as jaw crushers, impact crushers, crawler-type mobile crusher plants and tire-type mobile crusher plants, etc. If you want to know about the price of the new crusher machine, please contact us. We will give you the latest pricelist! Tags: cone crushers, cone crusher for sale, crusher machines, crusher machine for sale, crushing machine, fixed jaw crusher, impact crusher