If you are newcomers to the mining industry and want to open up a new world in this field, all you have to do is know the market and do all the preparations. Since the mining industry has become a highly competitive industry and all investors want to get a considerable return from it.

Some people have succeeded and made the size of the mining company grow larger while others may not succeed because they did not make good market analyses and preparations before do the mining process including identification of ore before mining, preparations for safety measures, how to efficiently obtain the local government’s mining permit. So if you are new to this industry, you must be fully prepared so that you can be foolproof and start a successful career.

Necessary training in the mining industry

Mining Safety training

No matter what industry you are in, safety is a top priority, especially for mining where safety is even more important. We always see in the news that a mining accident occurred in some areas of a country, or a worker was dead because of inadequate safety measures during construction. Therefore, it is necessary to carry out relevant safety training. Only when the safety concept is in place as well as safety measures and education of the company’s employees, can your mining enterprise proceed normally and orderly.

do enough mining safety supplies

How to get a mining permit?

Before mining, you must obtain a mining permit in order to make your next mine operation reasonable and legal. To be efficient and obtain qualifications in a short period of time, you must prepare in advance.

Make your personal mining qualified is important

What should you prepare to get the mining permit?

- Provide the plan in detail specified in mining law of your countries, such as the Mineral and Petroleum Resources Development Act

- Provide proof of financial and technical competence

- Provide detailed documentation that proves that the applicant has the technical capabilities and financial resources available or how it will be provided. This will enable applicants to carry out mining activities and mitigate and restore environmental impacts.

- Pay a certain application fee

- a copy of ID card

- Individual applicants must attach a certified copy of their identification documents.

- Certified copy of a certificate issued by the company and the Intellectual Property Commission.

- Copy of resolution (if acting as a representative)

- Apply for the necessary environmental authorization

- All applicants must apply for the necessary environmental authorizations under the National Environmental Management Act (NEMA) and the National Environmental Waste Management Act (NEWMA)

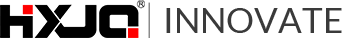

Mining process

1. Sampling

In order to determine the ore composition of the mine, sampling and analysis are required to mark the areas of ore and waste rock separately. Some hard ore areas should be blasted to loosen the rock and soil, and then excavated with an excavator. The dump truck is then used to tow the rock to the main crusher in the open-pit mine or from underground to the ore pile.

2. Crushing

The main concrete crushing machines located in the open-pit mine receives ore and waste at different times. These rock crushing equipment break larger rocks into sizes suitable for transport on conveyors.

3. Transport

Next, a belt conveyor or rubber conveyor is needed, which is about two kilometers in length. It can transport ore and waste stones from the open-pit to a ball mill for further grinding and crushing.

This mining process can be used in gold, copper,iron ore beneficiation

4. Grinding

The ball mill can classify the particle size of the ore, and repeatedly grind the large pieces to get the final product with less than 80% microns

5. Beneficiation

After the ball mill grinding the ore to a certain particle size, these rocks need to be put into the beneficiation equipment. Ore beneficiation plants divide the three most common methods which are gravity separation, flotation, and magnetic separation. They only operate in different ways and are commonly used in various beneficiation, gold beneficiation, copper, silver, etc.

6. Water treatment

After ores being are dewatered, some of the water in the embankment and the tailings pond is recovered for the grinding circuit. Excess water is pumped to a water treatment plant.

Common mining equipment

Stone crushing equipment

Crushing equipment is used to crush rocks. In order to achieve maximum productivity and high reduction rate, there are many different types of mine crushing equipment that can be used for a variety of tasks. The crushing equipment is specially configured to crush hard rocks into easy-to-control sizes for transportation. They are very valuable equipment in the industry because they reduce the costs associated with processing larger size materials and also ensure the effective release of useful elements in downstream processing of the material.

different types of crushing equipment

Ball mill

Because of its location, the position of the ball mill in the beneficiation production line is behind the crushing equipment and before the flotation or magnetic separator, in the middle. Secondly, after the ore is crushed by the crushing equipment, it needs to be further ground by the ball mill to get the qualified particle size then it can officially enter the beneficiation process.It can be seen that if there is no ball mill, then subsequent beneficiation operations could not be carried out.

different mining processing equipment

Magnetic separation equipment

Magnetic separation is a technique that separates iron ore from impurities based on their ferromagnetic differences. This separation method is widely used in the beneficiation of magnetite. The drum first with the permanent magnet rotates in the mud, and then the magnetic magnetite is attached to the surface of the drum and separated from the mud, while the non-magnetic impurities remain in the mud, thereby completing the separation. Magnetic separation is suitable for relatively fine ore with a diameter of about 0.05mm to 1mm.

Flotation equipment

Flotation is a technique that takes advantage of the difference in hydrophilicity of the surface of the ore. This technology is used for small diameter raw materials with a diameter of about 0.01mm to remove impurities such as sulfur and phosphorus. Iron ore and major impurities are similarly hydrophilic. However, the addition of chemicals that selectively adsorb to iron ore or impurities will make the surface adsorbed by the adsorbent hydrophobic. The bubbles are then captured by the hydrophobic surface and eventually float up to achieve separation.

Make a reasonable budget based on the actual project situation

The cost of setting up a mine and a concentrator can range from $ 500 million to $ 1 billion, depending on location, elements, ore grade, and various other factors. The following is an analysis of the economic feasibility of opening new mines and refineries based on factor prices driven by demand for those factors. The numbers used below reflect the typical cost budget of the industry. The purpose of this analysis is to illustrate the overall growth trend of the industry and give you a direction, not a specific value.

For example, a small-capacity mine produces an average of 20,000 tons of raw ore per day and runs 260 days per year in an 8-hour shift twice a day, while considering a large-capacity mine to produce an average of 200,000 tons per day. The raw mine can run for 350 days per year, three shifts per day, and 8 hours per shift. Since no specific location data is available, typical coverage values for this industry are used. The initial cost calculation was performed separately for the two silos, but both used the following general model:

Fixed Cost (The data comes from Massachusetts Institute of Technology)

=Capital Cost of Mining + Capital Cost of Refining

+Cost of Exploratory Studies + Other Fixed Costs

Operating Cost =Operating Cost of Mining + Operating Cost of Refining

The capital cost of mining is calculated using the following formula, where D is the daily production capacity of the mine in units of tons of ore produced per day. The constant in each calculation is based on the published industry average initial capital investment (for high-capacity mines defined in this analysis, approximately $ 500 million).

To calculate this period, the fixed capital cost of large mines is $ 400 million. The calculation assumes that this cost is divided equally into mining and refining, so the fixed capital cost of mining is $ 200 million. For small-capacity mines, 40% of the capital cost of large-capacity mines will be used based on the trends seen in the refining capital cost calculations. The variable part of the cost calculation is based on an open-pit mining model, which takes into account several factors that affect capital expenditure. Based on these, we can make a calculation:

Capital Cost (Small Capacity) = 80000000 + 160000 × D0.515

Capital Cost (Large Capacity) = 200000000 + 2670×D0.917

The average operating cost per ton of ore was also calculated using D:

Average Operating Cost (Small Capacity) = 71 × D-0.414

Average Operating Cost (Large Capacity) = 5.14 × D-0.148

the initial value of annual operating costs :

Annual Operating Cost = Average Operating Cost ×20000 tons/days ×260 days/year

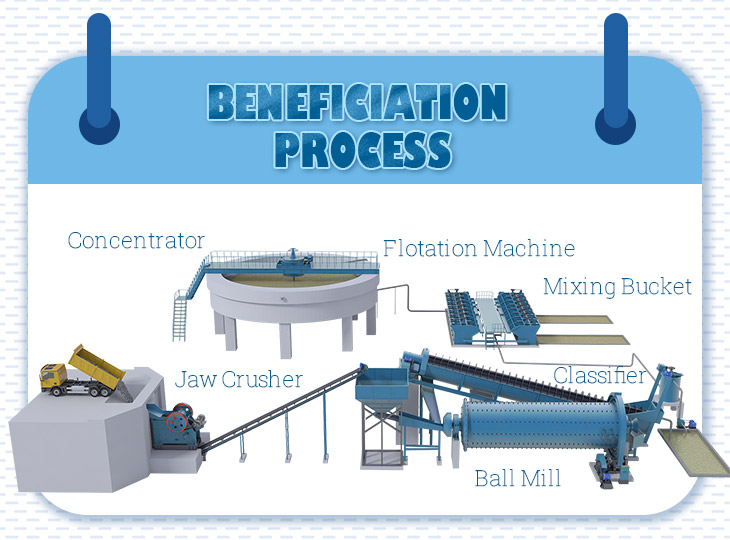

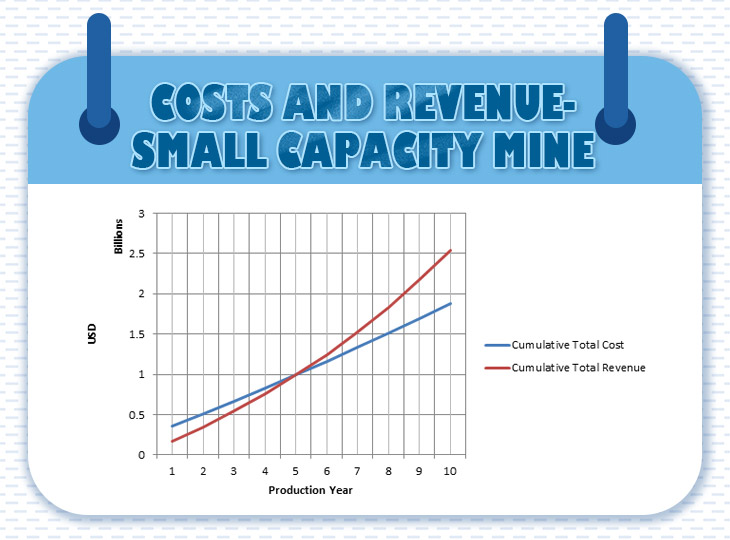

The figure below shows the cumulative expenditure and cumulative total revenue over time, and the difference between the two is the cumulative net income.

Note: this does not equal operating profit; the calculation takes into account initial capital expenditures.

cost of the small mining business

cost and revenue of the large mining business

For these predictions, the minimum average REO entry price (USD / kg) for each mine to be produced was determined. This calculation takes into account the average income required in the first year so that the cumulative total revenue is equal to the cumulative total production costs for the previous five years. Then, divide this value by the conversion factor (907.185 kg/ton) to calculate the lowest average purchase price of raw ore. The results are given in the following table:

| Different regions Output (t per year) | Entry Price ($/kg) |

| 2850 | 41.74 |

| 3000 | 41.03 |

| 5000 | 35.65 |

| 6500 | 33.78 |

| 7000 | 33.34 |

| 15000 | 29.36 |

| 15500 | 29.07 |

| 20000 | 27.14 |

| 25000 | 25.82 |

The graph shows the logarithmic relationship between expected annual production and entry price and shows that regressions are different for large and small mines. The opening of large mines and refineries is more economical than the opening of small mines. As we all know, the development cycle of large mines is longer than that of small mines. Obviously, mining at the site assessed is not only economically viable but also profitable.

the large mining process get more profits

Analysis of the mining industry outlook 2020

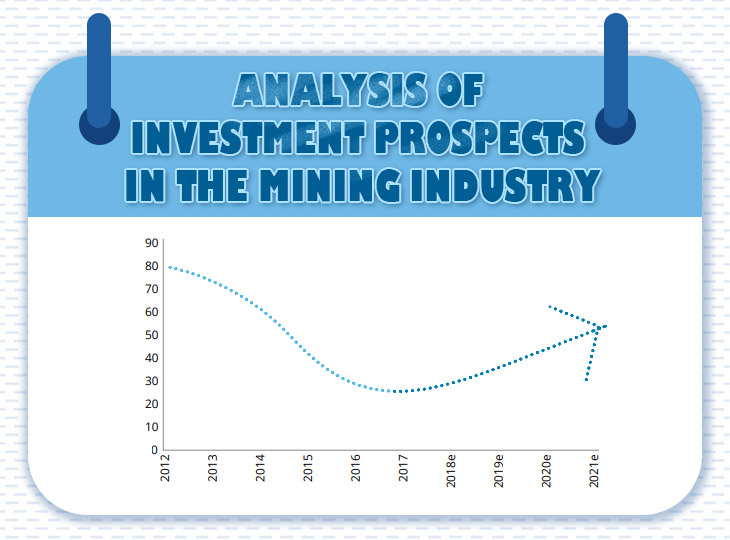

Since a high of more than 80 billion US dollars in 2012, capital expenditure in the mining industry has declined slightly. Analysis of mining data capital expenditure guidelines and market sentiment shows that capital expenditure is picking up. Even if the growth rate remains moderate, investment in 2020 is expected to exceed $ 40 billion.

The mining industry in 2020 still gets a bright future