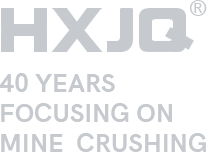

The crushing of materials is an indispensable process in the production of products in many industries ( such as metallurgy, mining, building materials, chemicals, ceramics, etc). Due to the difference in the physical properties and structural differences of the materials, the selection of the crusher should also be specifically analyzed. Based on the consideration of product performance, the crushing is divided into coarse crushing, medium crushing, fine crushing, etc., and various types of crushing equipment are also prepared accordingly.

different material granularity

In daily production, the most used crushers are: jaw crusher, cone crusher, impact crusher, hammer crusher, etc., and their finished products have different shapes, and the most critical factor is the difference between the feed port and the discharge port. So what are the characteristics of each machine’s feeding and discharging port?

Five crushers’ feeding and discharging port adjustment range

| Name | Feeding size(mm) | Discharging Size(mm) | Capacity(t/h) |

| Jaw crusher | 480-1200 | 60-300 | 120-1590 |

| Cone crusher | 70-500 | 6-41 | 36-2181 |

| Impact crusher | 250-800 | 10-20 | 30-800 |

| Hammer crusher | 600-1700 | 0-30 | 50-900 |

| Roller crusher | 25-30 | 2-10 | 5-110 |

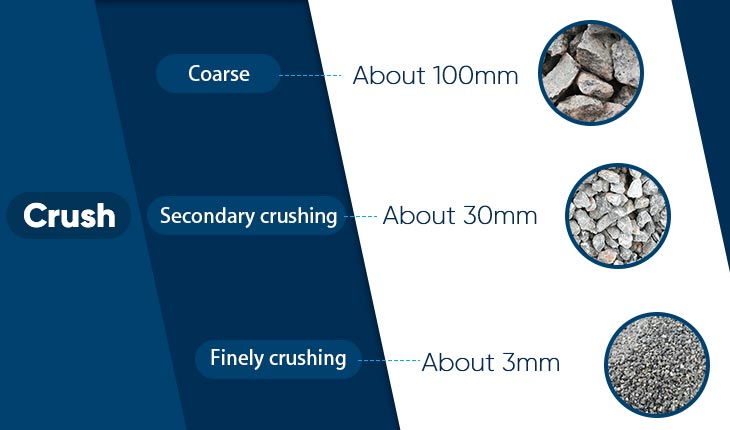

How to adjust the discharge of the jaw rock crusher?

The jaw crusher is mainly used for medium-sized crushing of various ores and bulk materials and can crush materials with compressive strength of not more than 320Mpa, which are divided into coarse and fine broken. The series of products are complete in specifications, and the feed size is 125mm ~ 750mm, which is the primary crushing equipment.

At present, the discharge port adjustment methods of jaw crushers with different structures are also different, mainly divided into three types: gasket type, wedge type, and cylinder type.

Gasket- type adjustment

PE jaw crusher and its discharging port

The washer being adjusted is usually located behind the bracket in the adjustment seat. When it is necessary to adjust the discharge opening, the number of the gaskets can be increased or decreased, and the total thickness of the gasket can be changed so that the front and rear positions of the brackets are changed. Besides, the front and rear positions of the lower part of the moving jaw are moved to realize the change of the discharge opening size. That method can be adjusted in multiple steps, the machine structure is relatively compact, and the weight of the device can be reduced, but it must be stopped when adjusting. Large-scale smashing uses this adjustment method.

| Model | Feeding size(mm) | Discharging Size(mm) |

| PE-150×250 | 150×250 | 10-40 |

| PE-200×300 | 200×300 | 15-50 |

| PE-200×350 | 200×350 | 18-70 |

| PE-250×400 | 250×400 | 20-60 |

| PE-400×600 | 400×600 | 40-100 |

| PE-500×750 | 500×750 | 50-100 |

| PE-600×750 | 600×750 | 150-200 |

| PE-600×900 | 600×900 | 65-160 |

| PE-750×1060 | 750×1060 | 80-140 |

| PE-800×1060 | 800×1060 | 130-190 |

| PE-900×1060 | 900×1060 | 230-290 |

| PE-900×1200 | 900×1200 | 95-165 |

| PE-1000×1200 | 1000×1200 | 195-265 |

| PE-1200×1500 | 1200×1500 | 150-350 |

| PE-1500×1800 | 1500×1800 | 220-350 |

| PEX-150×750 | 150×750 | 18-48 |

| PEX-250×750 | 250×750 | 25-60 |

| PEX-250×1000 | 250×1000 | 25-60 |

| PEX-250×1200 | 250×1200 | 25-60 |

| PEX-300×1300 | 300×1300 | 20-90 |

wedge-type adjustment

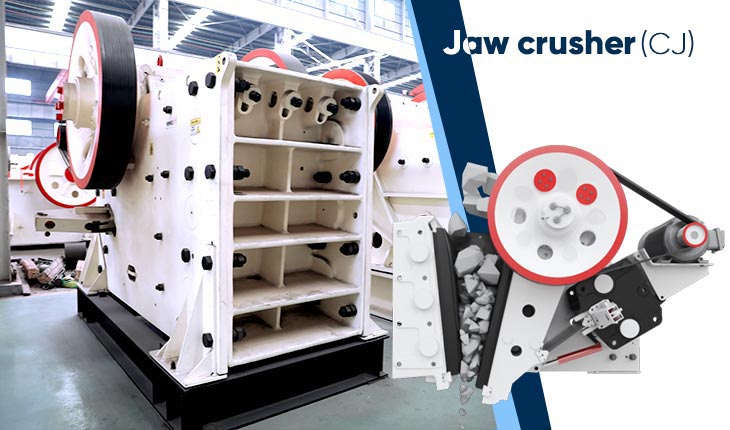

CJ Euro jaw crusher is the most advanced type

The wedge block adjustment device consists essentially of two identical wedge blocks. The wedge block is located on the inclined surface of the two wedge blocks at the rear of the bracket seat. By changing the relative positions of the two wedge blocks, the total thickness of the pair of wedge blocks can be changed, thereby changing the position of the front and rear of the bracket. The front and rear positions of the lower part of the moving jaw are moved to realize the change of the size of the discharge opening.

| Model | Feeding size(mm) | Discharging Size(mm) |

| CJ96 | 480 | 60-175 |

| CJ106 | 560 | 70-200 |

| CJ125 | 960 | 100-250 |

| CJ150 | 960 | 150-300 |

| CJ200 | 1200 | 175-300 |

| CJ1511 | 850 | 125-300 |

| CJ1513 | 1040 | 150-300 |

Hydraulic cylinder way

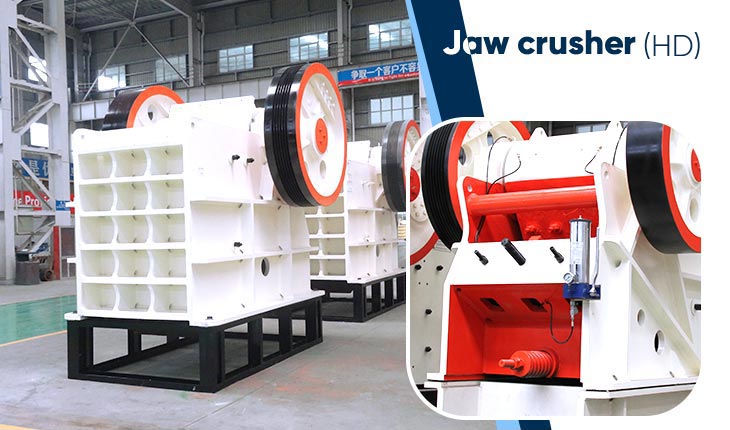

The hydraulic cylinder discharge port of HD jaw crushers

Hydraulic cylinder discharge port is just like a large oil cylinder in the middle of the bracket so that the length of the bracket becomes a step-less adjustment change, thereby changing the front and rear position of the moving jaw to realize the row adjustment of the size of the material. The discharge port adjusting device of the structure can not only automatically adjust the size of the discharge opening but also realize the function of the iron and the clear cavity, it also can greatly facilitate the operation and reduce the labor intensity. Such a jaw crusher is costly to manufacture and imposes high demands on the worker’s handling and maintenance skills.

| Model | Feeding size(mm) | Discharging Size(mm) |

| HD72(57) | 425 | 45-100 |

| HD86(69) | 500 | 50-150 |

| HD98(751) | 630 | 75-175 |

| HD110(912) | 750 | 100-200 |

| HD125 | 900 | 125-225 |

What to do when it comes to the gold cone crusher?

The main shaft of the multi-cylinder hydraulic cone crusher is fixed, and the hydraulic pusher or the hydraulic motor drives the adjusting ring through the adjusting cap to rotate in the support sleeve for adjusting the size of the discharge opening. The main shaft of the single-cylinder hydraulic cone crusher is rotated, which under the action of the hydraulic cylinder makes the main shaft being lifted or lowered to adjust the discharge opening size.

| Model | Chamber | Feeding size(mm) | Discharging Size(mm) |

| SC100S | C1 | 250 | 22 |

| C2 | 200 | 19 | |

| SC160S | C1 | 360 | 25 |

| C2 | 300 | 22 | |

| SC250S | C1 | 450 | 35 |

| C2 | 400 | 29 | |

| SC315S | C1 | 560 | 41 |

| C2 | 500 | 38 |

Compared with the multi-cylinder hydraulic cone crusher, the requirements for single-cylinder hydraulic cone breaking technology and material selection are more advanced and strict. It is used to crush all kinds of medium hard and abrasive materials with compressive strength of the material are less than 100MPa and the water content is less than 15%, and the crushed materials are coal, salt, gypsum, brick, limestone and so on.

multi-cylinder hydraulic cone crushers

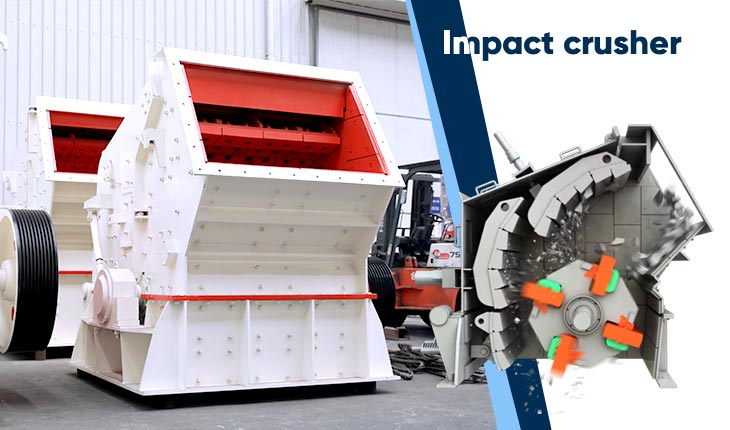

How to adjust the discharge port of impact rock crusher?

There is no purlin screen in the lower part of the impact crusher, which causes the particle shapes is controlled by adjusting the rotor speed or rotor diameter, adjusting the size of the feeder opening, or adjusting the gap of the grinding chamber. Under normal circumstances, it can process materials with a side length of 100-500mm, and its compressive strength can reach up to 350MPa. It has the characteristics of large crushing ratio, cubic material after crushing, uniform particle size, etc. It is widely used in stone crushing of highway engineering.

| Model | Feed Opening Size(mm) | Max. Feeding Size(mm) |

| PF-1007 | 400×730 | 300 |

| PF-1010 | 400×1080 | 350 |

| PF-1210 | 400×1080 | 350 |

| PF-1214 | 400×1430 | 350 |

| PF-1315 | 860×1520 | 500 |

| PF-1320 | 993×2000 | 500 |

| PF-1520 | 830×2040 | 700 |

| PF-1820 | 1260×2040 | 800 |

The right way is to adjust the gap of the grinding chamber

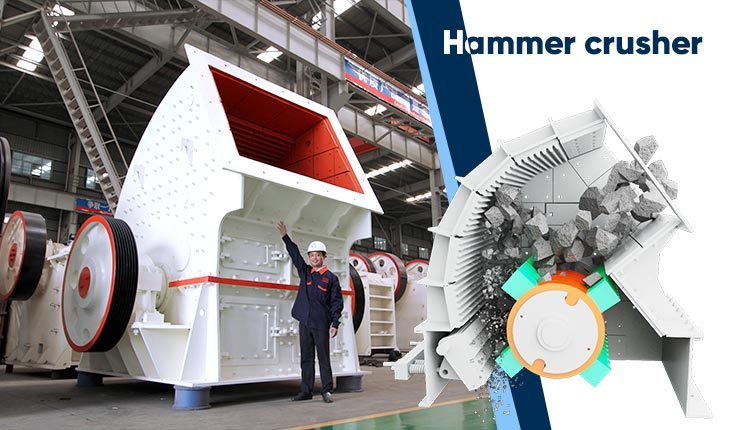

What should I do when it comes to the hammer crusher?

The hammer crusher controls the product size by adjusting the size of the screen gap, which is suitable for crushing minerals of various brittle materials. The compressive strength of the material does not exceed 100 MPa and the humidity is not more than 15%. In general, the overall allowable feeding size of the hammer crusher is still large, which normally can reach 100-3000 thp, and the feeding range is from 500-1200mm. This is also why in the case of crushing materials with little hardness, such as limestone, bluestone, and dolomite, the hammer break is more suitable for coarse crushing, that is, primary crushing.

| Model | Feed Opening Size(mm) | Max. Feeding Size(mm) |

| PCZ1308 | 910×890 | ≤400 |

| PCZ1410 | 1020×750 | ≤500 |

| PCZ1610 | 1150×1000 | ≤600 |

| PCZ1615 | 1400×1000 | ≤600 |

| PCZ1716 | 1640×1300 | ≤650 |

| PCZ1720 | 1980×1300 | ≤650 |

| PCZ1920 | 1850×1600 | ≤800 |

| PCZ2225 | 2100×2300 | ≤1200 |

Large stones are coarsely crushed by the hammer crusher, the particle size is usually reduced to between 50 and 100 mm. A hammer crusher with a yield of fewer than 400 tons can be broken into a broken shape, that is, the large stone is directly broken to the common stone specifications. The material after being crushed by the hammer crusher which is over 400 tons for the preliminary processing, needs further shaping by medium or fine crushing equipment to meet the qualified final product shape.

PCZ hammer crushers can greatly improve the efficiency

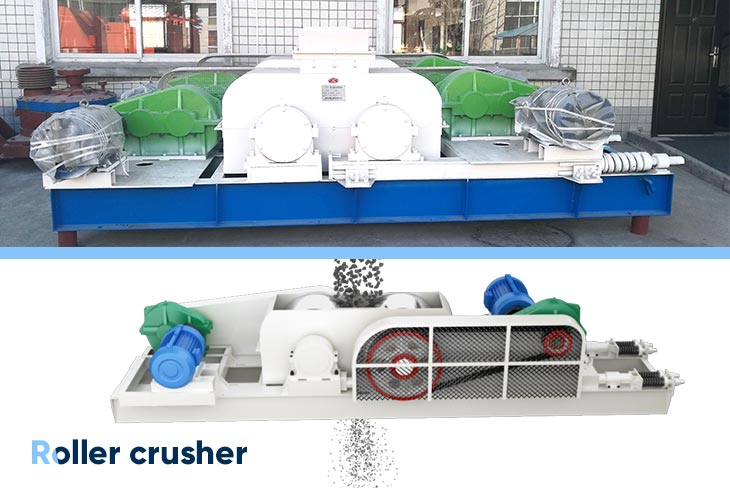

What should I do to adjust the discharge port of the roller crusher?

The roller crusher (double roll crusher) is suitable for coarse and medium-sized crushing of brittle bulk materials in cement, chemical, electric power, mining, metallurgy, building materials, refractory materials, coal mines, etc. Besides, its feed size is large, and the discharge granularity is adjustable, can crush materials with compressive strength ≤160MPa.

| Model | Feed Opening Size(mm) | Discharging Size(mm) |

| 2PG0425 | ≤25 | 2-8 |

| 2PG0640 | ≤25 | 2-8 |

| 2PG0740 | ≤25 | 2-8 |

| 2PG0850 | ≤25 | 2-8 |

| 2PG1060 | ≤30 | 2-10 |

| 2PG1260 | ≤30 | 2-10 |

| 2PG1560 | ≤30 | 2-10 |

Adjusting the discharge granularity: a wedge or washer adjustment device is arranged between the two rollers, and the top end of the wedge device is provided with an adjusting bolt. When the adjusting bolt pulls the wedge upward, the wedge pushes the movable roller away from the fixed wheel. That is, the gap between the two rollers becomes larger as well as discharge granularity.

Roller crushers can produce a various degree of material granularity

When the wedge is downward, the gap between the two movable rollers becomes smaller under the action of the pressing spring so that the discharge granularity becomes smaller. The gasket device adjusts the size of the discharge by increasing or decreasing the number or thickness of the gasket. When the gasket is added, the gap between the two rollers becomes larger. When the gasket is reduced, the gap between the two rollers becomes smaller, so as to the discharge granularity becomes smaller.

Conclusion

From above we know that different kinds of crushers have different ways of adjusting the discharging ports. In terms of which one can meet your demands depending on the real project and the situation. Here we offer you a crusher’s price list for your further reference. If you want to purchase any one of them and get a very reasonable price, HXJQ China must be the best choice for you cause here we provide the best pre-sale and after-sale services for you and advise you the best plan for shipping and machine selecting.

| Name | Price (according to Alibaba) |

| Jaw crusher | $2,000.00-$6,600.00 |

| Cone crusher | $4,500.00-$100,000.00 |

| Impact crusher | $3,888.00-$140,000.00 |

| Hammer crusher | $1,000.00-$8,000.00 |

| Roller crusher | $50,000.00-$200,000.00 |