What is the list parts when I want to homemade a concrete crusher?

What are the most important parts of concrete crushers? Just taking a fixed jaw crusher as an example, the most important parts of it are fixed jaw faces and moving jaw faces, which are the key wear parts of the crushing equipment. The quality of the wear parts directly settles down the service life of the jaw plate no matter it is fixed or moveable so that we must choose the high-quality ones. At the market, although high-manganese steel is partially replaced by other steel grades under low-stress and medium-stress-impact abrasive wear conditions, it still has an important position in wear-resistant materials due to its low production process requirements and wide range of raw materials.

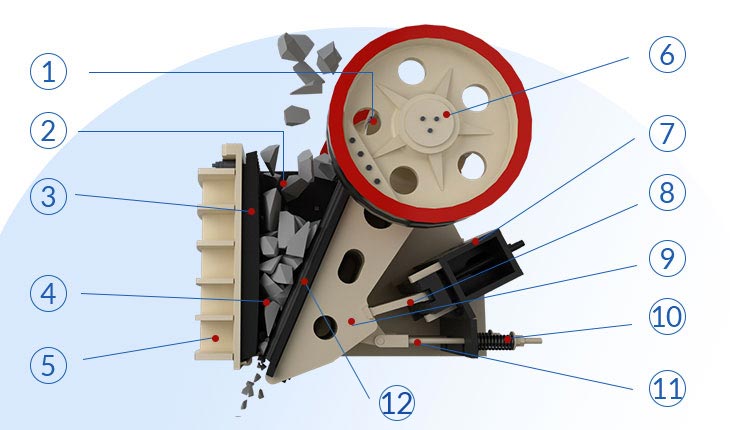

| Number | Name |

| 1 | Guard plate |

| 2 | Upper guard plate |

| 3 | Fixed jaw plate |

| 4 | Down guard plate |

| 5 | frame |

| 6 | Mobile jaw |

| 7 | Set adjustment |

| 8 | spring |

| 9 | toggle |

| 10 | Toggle gasket |

| 11 | tension |

| 12 | Mobile jaw plate |

How to complete the assembly process of the crushing equipment? (video)

During the installation, there are five tips that you should follow

Jaw crusher framework installation

When installing the crusher framework, some things that can absorb vibration, such as hardwood, rubber, etc., should be placed between the frame and the concrete.

The installation must address the requirements no matter what is on the foundation or the horizontal and vertical levels on the wooden seat. In general, the horizontal and vertical levels should be less than 0.2mm.

Points of eccentric shaft and bearing assembly

Before the shaft and bearing assembly, you have to match orderly the sliding bearing and then place them in the sliding bearing housing. During the process, you can test horizontality and coaxiality by gradienter until the measurement result meets the requirements and then Installing the eccentric shaft on the bearing. The next important thing is viewing the fit between the shaft and the bearing by applying red lead powder on the journal.

Jaw rod installation

After the above part is installed in place, the connecting rod can be installed. Before the rod is assembled, the position of the connecting rod and the required assembly should be carefully checked. Then, lift the rod and use gasoline or kerosene to clean the whole connection for the next applying the surface of the connecting rod to ensure good lubrication.

Jaw crusher ribs’ installation

The concrete jaw crusher rib can be removed by loosening the tension spring nut, removing the spring, using a chain or a wire rope to smash the lower part of the shovel, and then pulling the wire rope by the car. Only in that way, you can make the moving jaw close to the fixed raft but then the rib is automatically drop off, so just repeat the above steps in the installation.

You can learn how to configure PE jaw crusher step by step through video(The source format:https://youtu.be/5kYs-AoMHQY)

At the same time, the coaxiality and inclination of the sliding bearing assembly should first be tested by ensuring that the inclination is 0.2mm and the coaxiality is less than 0.06mm to complete the assembly of the movable jaw。

Moving jaw installation

Firstly, assemble the moving parts accordingly including the moving jaws, moving shafts, movable plates, rib pads, etc. , and then the assembled parts should be hoisted together in the crusher framework by using a crane.

At the same time, the coaxiality and inclination of the sliding bearing assembly should be detected firstly by the way the inclination is guaranteed to be 0.2 mm and coaxiality less than 0.06 mm to complete the assembly for the moving jaw.

Jaw crusher tooth plate Installation

The jaw crusher tooth plate is a component used directly for crushing ore. Its structure is simple, but it often needs to be replaced due to frequent contact with the ore. The cross-sectional structure of the tooth plate has two types one of which is a smooth surface, the other is a lattice-type surface. Due to the large weight and it needs to be made into an easily replaceable structure.

The tooth plate is fixed by bolts or wedges and is fixed on the front wall of the frame or on the movable jaw and the contact surface between the two must be straight. Since the inner side of the front wall is not machined, a soft metal gasket is placed between the back of the fixed tooth plate and the front wall to ensure the tightness of the combination.

From the video, we know how to configure the jaw crusher, but before it can fully enter the production line, we must be fully prepared:

| No-load test | On-load test |

| When running for 2 hours, bearing temperature should less than 30℃ |

When running for 8 hours, bearing temperature should less than 30℃ |

| All fasteners should be firm and free of looseness |

The jaw crusher must not have periodic or significant impact sound |

| The flywheel and the sheave are running smoothly |

The maximum feed size should meet the design requirements |

| All friction parts are free from scratches, chipping and grinding without abnormal sound |

Carefully check that the lubrication of the bearing |

| The adjusting device of the discharge opening should ensure the adjustment range of the discharge opening |

Check if there is any debris in the crushing chamber |

Where can I buy these high-quality concrete jaw crusher parts?

HXJQ Machinery Provides a variety of crusher and crusher parts

It is well known that products made in China are now known for their affordable prices and high quality due to relatively low labor costs. Many foreign customers are very full of the products they buy. Therefore, if you want to buy crusher parts in China, there are many large mining equipment manufacturers like HXJQ, which is the most famous supplier of portable stone crushers and various high-quality and long service-life parts.